How to Keep Your Automotive Shop Running Safely and Efficiently

Running an automotive shop isn’t just about fixing cars—it’s about maintaining a safe, organized, and productive workspace. From managing hazardous fumes to ensuring high-quality paint finishes and keeping work areas clean, shop owners face multiple challenges that can impact efficiency and compliance.

With the right strategies and custom solutions, you can create a shop environment that is not only safer but also more productive and cost-effective. Let’s explore how CPL Group’s automotive solutions can help you overcome industry challenges while boosting your shop’s performance.

Common Challenges in Automotive Shops

1. Airborne Contaminants and Fume Management

Welding, grinding, painting, and chemical treatments release harmful fumes that can:

- Cause respiratory problems for employees

- Lead to violations of workplace safety regulations

- Reduce overall productivity due to poor air quality

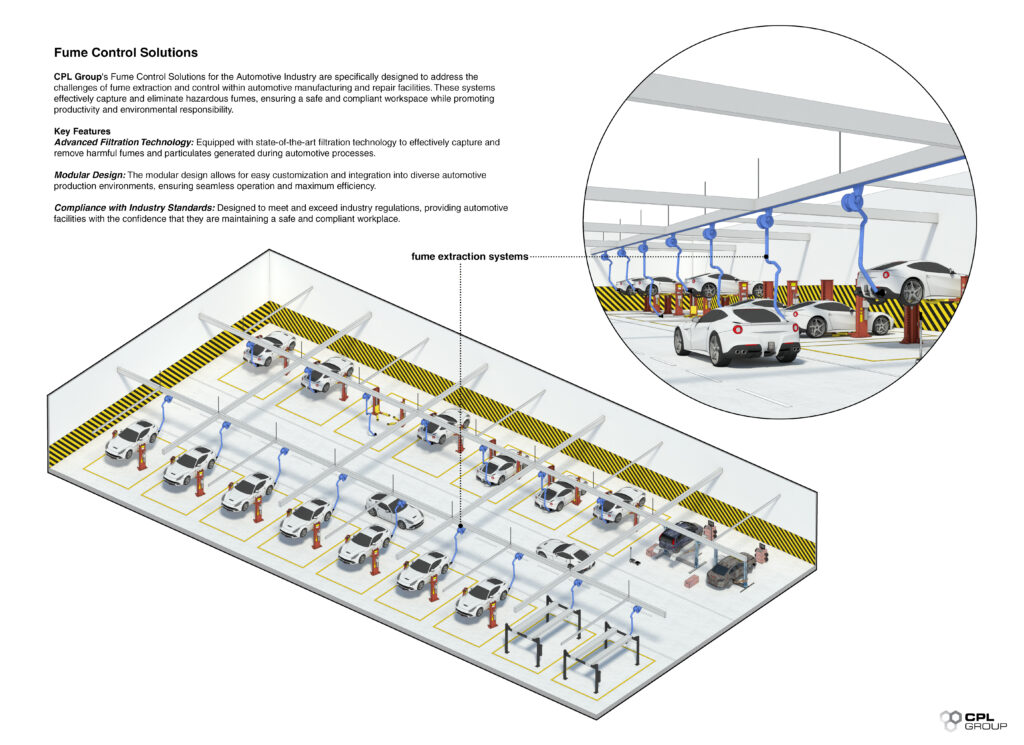

✅ Solution: CPL Group’s Fume Control Solutions remove airborne contaminants at the source, ensuring a healthier workspace and keeping your shop in compliance with OSHA and EPA air quality regulations. A cleaner environment means fewer sick days and higher worker efficiency.

2. Maintaining a High-Quality Paint Finish

Painting is a critical part of many automotive repairs, but dust, poor ventilation, and improper lighting can lead to:

- Uneven coatings and defects requiring rework

- Wasted paint, increasing material costs

- Safety hazards due to prolonged exposure to fumes

✅ Solution: CPL Group’s Paint Bays provide a controlled, dust-free environment with proper ventilation and lighting, ensuring high-quality finishes the first time. This reduces material waste and improves turnaround time, making your shop more efficient.

3. Keeping Workspaces Clean and Compliant

Automotive shops deal with water, grease, and chemical spills, which can:

- Create safety hazards like slips and falls

- Damage expensive equipment

- Lead to non-compliance with cleanliness regulations

✅ Solution: CPL Group’s Wash Down Curtains help contain water and cleaning chemicals, keeping your workspace organized and compliant with industry hygiene standards. A clean shop prevents downtime caused by accidents and equipment damage.

Productivity Tips for a More Efficient Shop

???? Invest in Proper Ventilation – Good airflow reduces fumes and heat buildup, keeping employees comfortable and focused.

???? Use Dedicated Paint Bays – Minimize rework and save time by ensuring a controlled environment for painting and refinishing.

???? Organize Workspaces – Keep tools and equipment in designated areas to streamline workflow and reduce downtime.

???? Implement Regular Cleaning Protocols – Use washdown curtains and cleaning zones to maintain a tidy, compliant shop.

???????? Prioritize Employee Safety – A safe work environment reduces absenteeism and increases overall efficiency.

Staying Compliant with Industry Regulations

Regulatory bodies like OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency) set strict standards for air quality, hazardous materials, and shop cleanliness. Non-compliance can result in heavy fines and operational shutdowns.

By implementing CPL Group’s fume control, paint bays, and washdown solutions, your shop stays ahead of compliance requirements while improving workplace safety and efficiency.

Why CPL Group?

✔ Custom Solutions for Your Shop’s Needs

✔ Regulatory Compliance Assurance

✔ Enhanced Productivity & Cost Savings

✔ Healthier Work Environment for Employees

Keep your automotive shop running safely and efficiently with the right solutions. Learn more about CPL Group’s custom automotive solutions here: CPL Group Automotive Solutions