Freezer Panels for Cold Storage: Enhancing Efficiency, Reliability & Temperature Control

Maintaining consistent low temperatures is essential across food production, logistics, pharmaceuticals, and industrial storage. As demand for high-performance cold-chain infrastructure grows, businesses are increasingly turning to insulated freezer panels as a smarter, more efficient alternative to traditional cold-room construction.

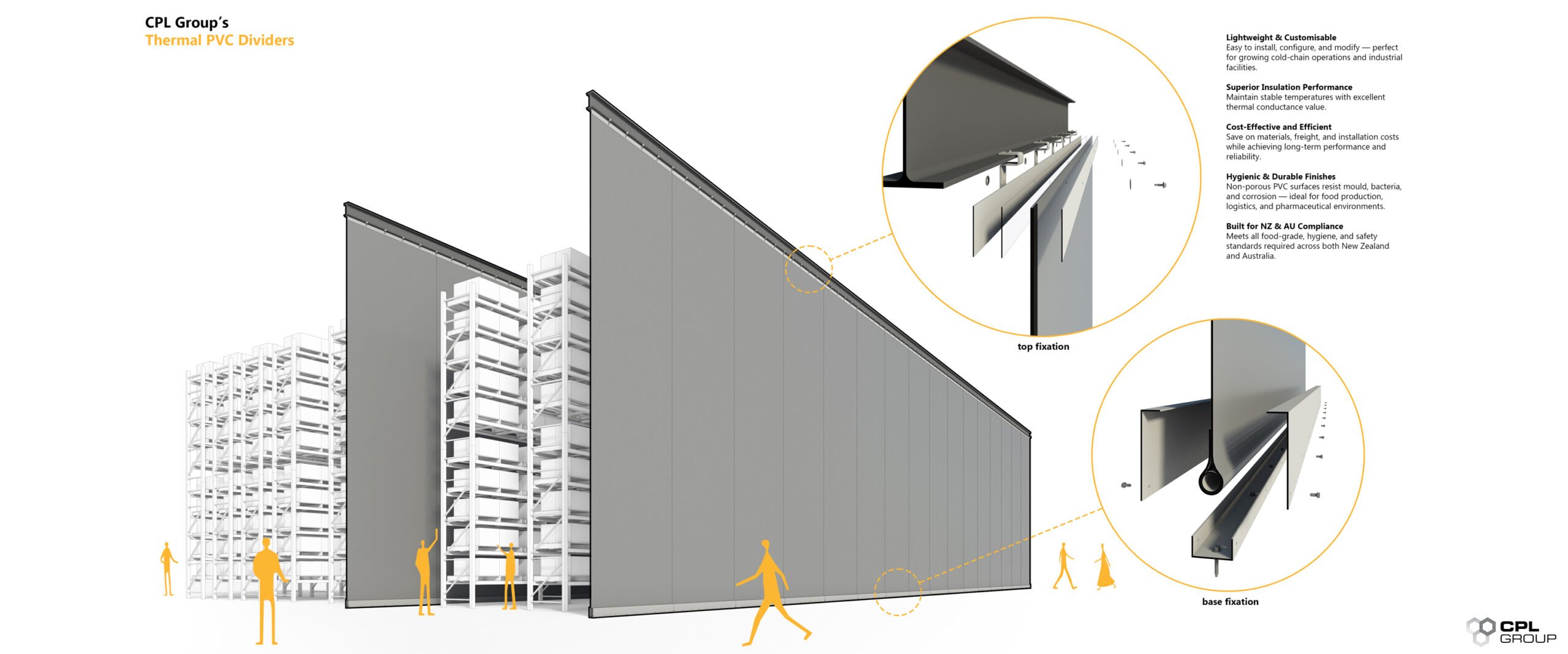

CPL Group’s Freezer Panels are designed to deliver superior thermal performance, durability, and long-term energy savings—making them an essential building block for any modern cold-storage facility.

What Are Freezer Panels for cold storage?

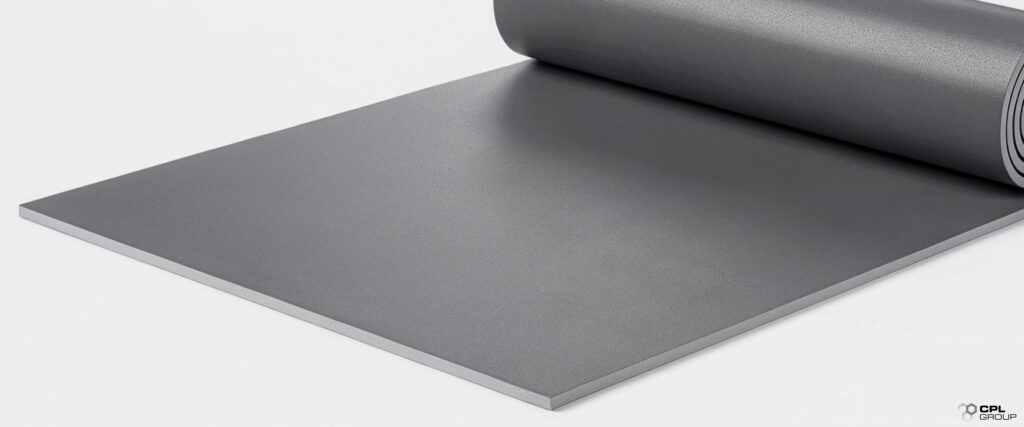

Freezer panels for cold storage are insulated, modular panels designed specifically for use in low-temperature environments. They create tightly sealed, temperature-controlled spaces ideal for freezers, cool rooms, and cold-chain warehousing.

Constructed with high-performance insulation cores and durable external skins, freezer panels offer:

- Exceptional thermal insulation

- Reduced heat transfer

- Moisture resistance

- Long-term structural reliability

Their modular nature allows for rapid installation and total design flexibility—making them an ideal solution for new builds, expansions, or facility upgrades.

Why Thermal Performance Matters in Cold Storage?

Energy is the single biggest operating cost in cold-chain facilities. Poor insulation or temperature leakage forces refrigeration systems to work harder, impacting product integrity and increasing power usage.

CPL’s freezer panels help solve this challenge by providing:

✔ High R-Values for Stable Low Temperatures

The panels are engineered to deliver superior insulation performance, maintaining consistent internal temperatures and reducing the risk of spoilage or quality degradation.

✔ Lower Energy Consumption

By minimising heat ingress, freezer panels significantly reduce refrigeration load—helping businesses cut energy consumption and operational costs.

✔ Improved Temperature Recovery

In high-traffic environments, such as picking zones or loading docks, rapid temperature recovery is essential. Strong insulation ensures faster stabilisation and better overall efficiency.

Key Features of CPL Group’s Freezer Panels for cold storage

CPL’s freezer panels are engineered to perform in demanding environments. Key features include:

1. Superior Thermal Insulation

Optimised to maintain ultra-low temperatures required for frozen goods, pharmaceuticals, and precision-controlled environments.

2. Hygienic, Easy-Clean Surfaces

Smooth, durable surfaces prevent moisture buildup and are resistant to bacteria—ideal for HACCP-compliant facilities.

3. Rapid Installation with Minimal Downtime

The modular panel system allows for quick construction, enabling new facilities to go live faster or existing sites to be upgraded with limited disruption.

4. Moisture & Corrosion Resistance

Designed to withstand condensation, washdowns, and long-term exposure to low temperatures.

5. Fully Customisable Configuration

Panels can be tailored to suit:

- Freezer rooms

- Chill rooms

- Processing areas

- Multi-zone warehouses

- Walk-in freezers

- Distribution centres

Whether you’re building a small freezer room or a large-scale cold-storage complex, CPL can design a panel system that matches your performance and regulatory requirements.

Applications of Freezer Panels

Freezer panels are widely used across industries that rely on precise temperature control, including:

- Food processing & manufacturing

- Cold and frozen goods warehousing

- Pharmaceuticals & medical storage

- Hospitality & retail cold rooms

- Logistics & distribution centres

- Agriculture & seafood processing

Their adaptability makes them a scalable solution for both small operators and large industrial facilities.

Benefits of Using Freezer Panels in Modern Cold Storage

✔ Improved Energy Efficiency

Reduced heat transfer lowers refrigeration demand and drives long-term cost savings.

✔ Enhanced Product Quality & Safety

Consistent, controlled temperatures protect product integrity throughout storage.

✔ Faster Construction & Reduced Labour Costs

Prefabrication ensures clean installation, reduced labour, and predictable deployment timelines.

✔ Long-Term Durability

Built to withstand the harsh conditions of cold and frozen environments.

✔ Future-Proof Scalability

Panels can be added, removed, or reconfigured as your cold-storage needs evolve.

Why Choose CPL Group for Freezer Panels for cold storage?

CPL Group is a trusted supplier of thermal solutions across Australasia, delivering high-quality freezer panels backed by decades of industry expertise.

With a focus on innovation, efficiency, and reliability, CPL provides:

- Custom-engineered panel solutions

- High-performance insulation options

- Technical advice and project support

- End-to-end supply and installation

Whether you’re building a new cold-storage facility or upgrading existing infrastructure, CPL ensures a reliable, high-performing result tailored to your operational needs.

Ready to Enhance Your Cold-Storage Efficiency?

CPL’s freezer panels deliver the insulation performance, durability, and modular flexibility you need to build a facility that’s efficient today and scalable for tomorrow.

➡️ Learn more about CPL Freezer Panels: https://cplgroup.com/industries/freezer-panels/