Manufacturing Efficiency with Tailored Solutions

In the competitive world of manufacturing, efficiency is key. CPL Group offers tailored solutions to optimize manufacturing processes, ensuring maximum productivity and minimal downtime.

The Need for Tailored Solutions

Every manufacturing process is unique, with specific challenges and requirements. Tailored solutions ensure that your operations are optimized to meet your specific needs.

Key Areas of Optimization:

- Workflow Management: Streamlining processes to reduce bottlenecks and improve throughput.

- Resource Utilization: Maximizing the use of materials and labor to enhance productivity.

- Technology Integration: Incorporating advanced technologies to enhance efficiency and reduce manual labor.

- Safety Enhancements: Implementing safety protocols to protect workers and equipment, ensuring a safe working environment.

CPL Group’s Approach

Our team works closely with you to understand your unique challenges and develop customized solutions. From initial assessment to implementation, we ensure that our solutions align with your operational goals.

Key Areas for Optimization

- Workflow Management

- Assessment: Evaluate current workflows to identify inefficiencies and bottlenecks.

- Design: Develop streamlined processes to improve throughput and reduce delays.

- Implementation: Utilize technology and best practices to optimize workflow.

- Tips for Workflow Management:

- Map Out Processes: Visualize your workflow to identify and eliminate bottlenecks.

- Automate Repetitive Tasks: Use automation to reduce manual labor and increase consistency.

- Continuous Improvement: Regularly review and refine processes to maintain efficiency.

- Resource Utilization

- Assessment: Analyze the utilization of materials, labor, and equipment.

- Optimization: Implement strategies to maximize resource use and minimize waste.

- Monitoring: Continuously monitor resource usage to ensure efficiency.

- Tips for Resource Utilization:

- Track Metrics: Use KPIs to measure and optimize resource usage.

- Lean Manufacturing: Adopt lean principles to eliminate waste and improve efficiency.

- Employee Training: Train staff on best practices for resource management.

- Technology Integration

- Assessment: Identify opportunities for technology integration to improve efficiency.

- Implementation: Integrate advanced technologies like IoT, automation, and AI.

- Training: Ensure employees are trained to use new technologies effectively.

- Tips for Technology Integration:

- Scalable Solutions: Choose technologies that can scale with your business.

- Data-Driven Decisions: Use data analytics to inform technology integration.

- Collaborative Tools: Implement tools that enhance collaboration and communication.

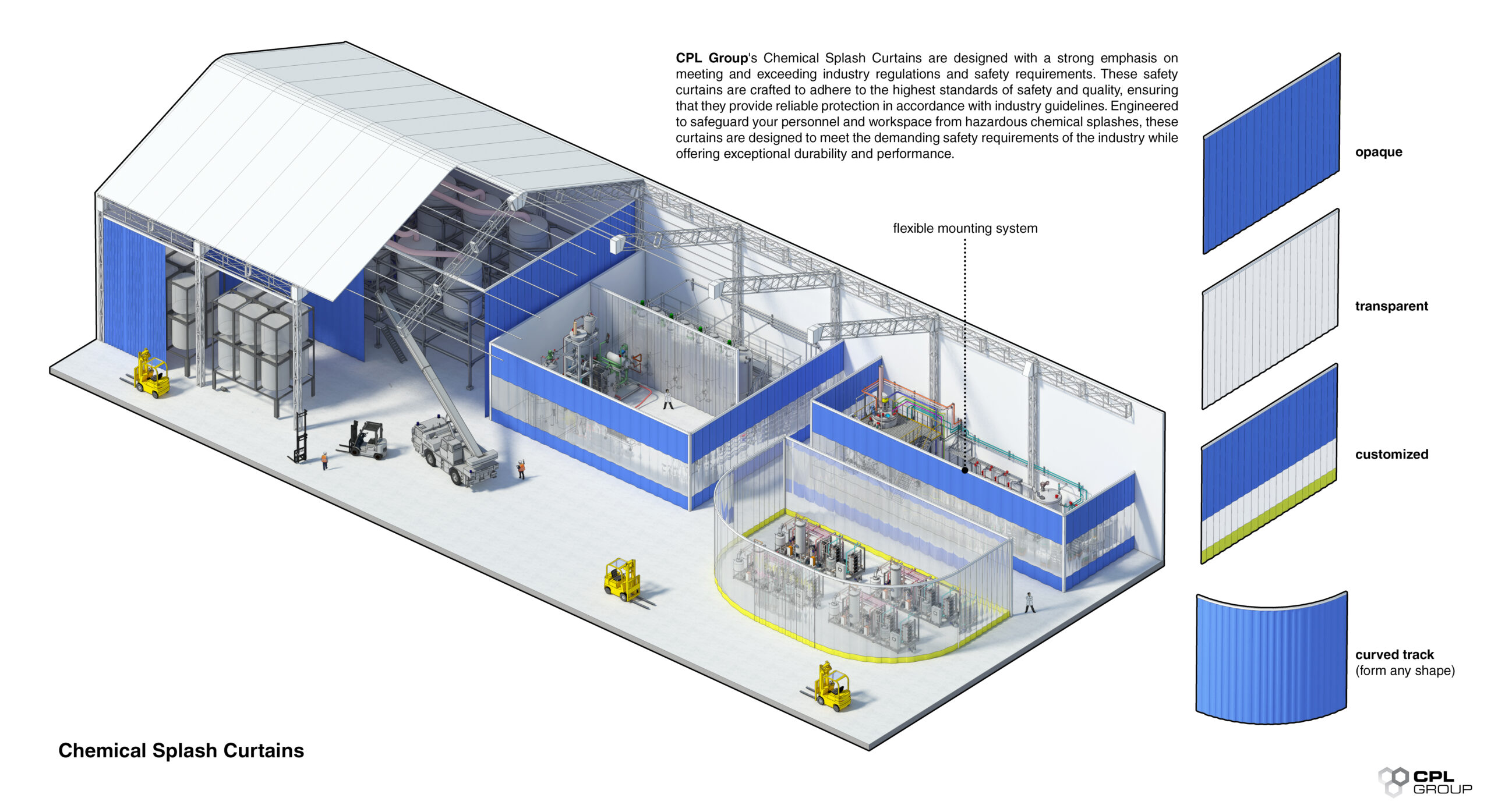

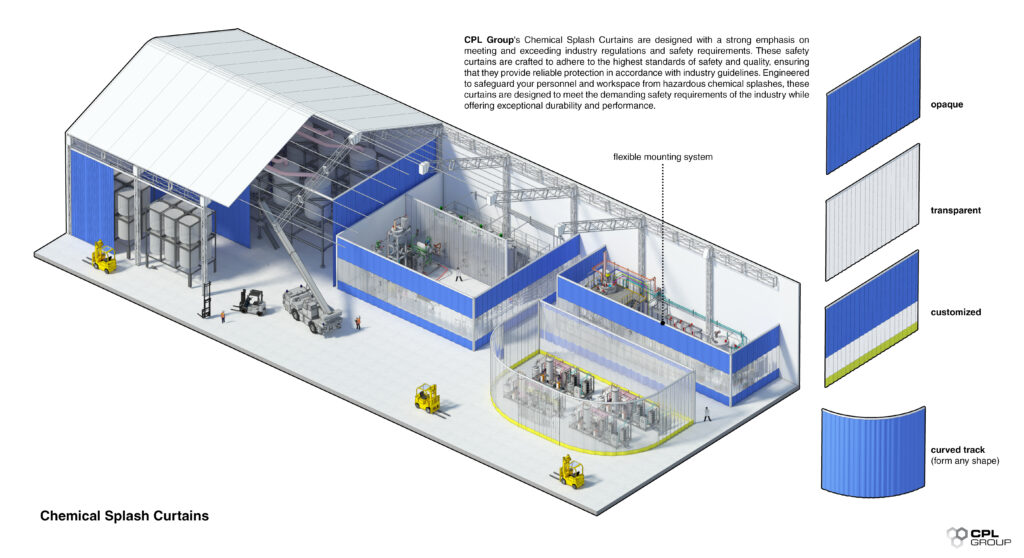

- Safety Enhancements

- Assessment: Evaluate current safety protocols and identify areas for improvement.

- Implementation: Install safety barriers, curtains, and other protective measures.

- Training: Conduct regular safety training and drills for employees.

- Tips for Safety Enhancements:

- Regular Audits: Conduct regular safety audits to identify and address risks.

- Safety Culture: Foster a culture of safety through ongoing training and awareness.

- Compliance: Ensure compliance with all relevant safety regulations and standards.

CPL Group’s Approach

Our team works closely with you to understand your unique challenges and develop customized solutions. From initial assessment to implementation, we ensure that our solutions align with your operational goals.

- Industrial Containment Booms: Effective for managing spills and leaks, ensuring environmental compliance and safety. These booms are designed to contain hazardous substances, preventing them from spreading and causing environmental damage.

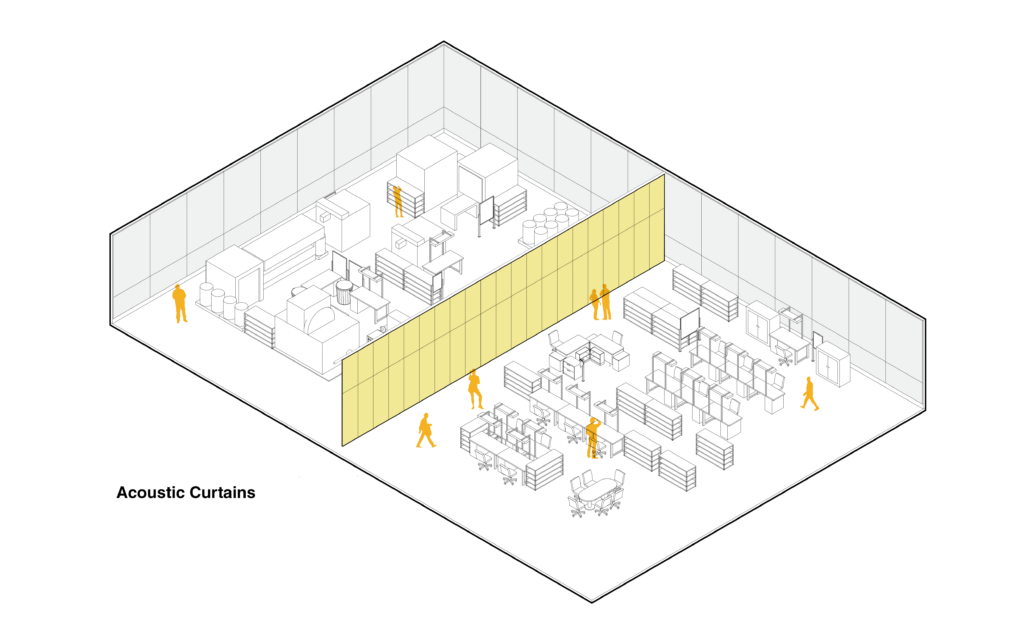

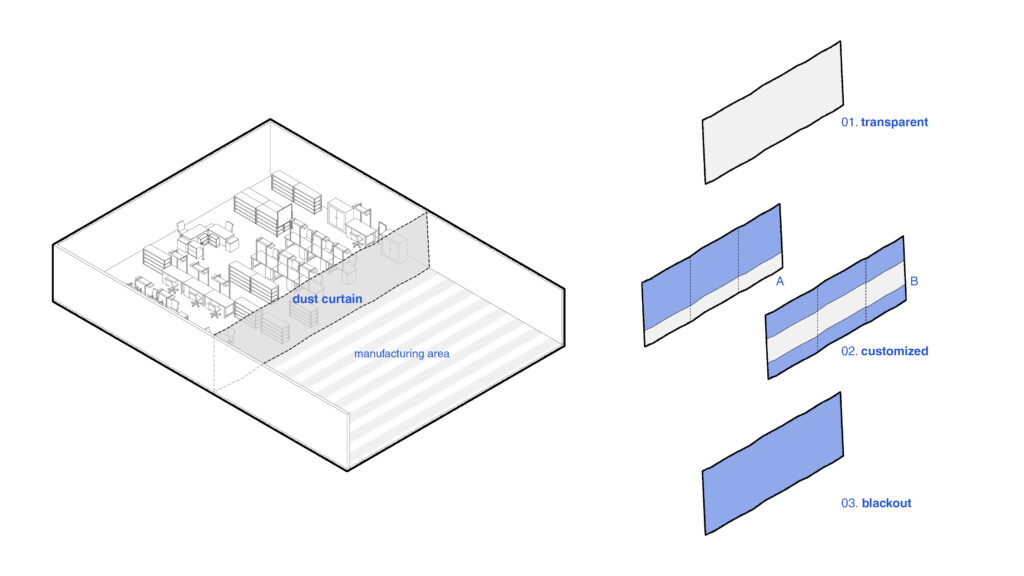

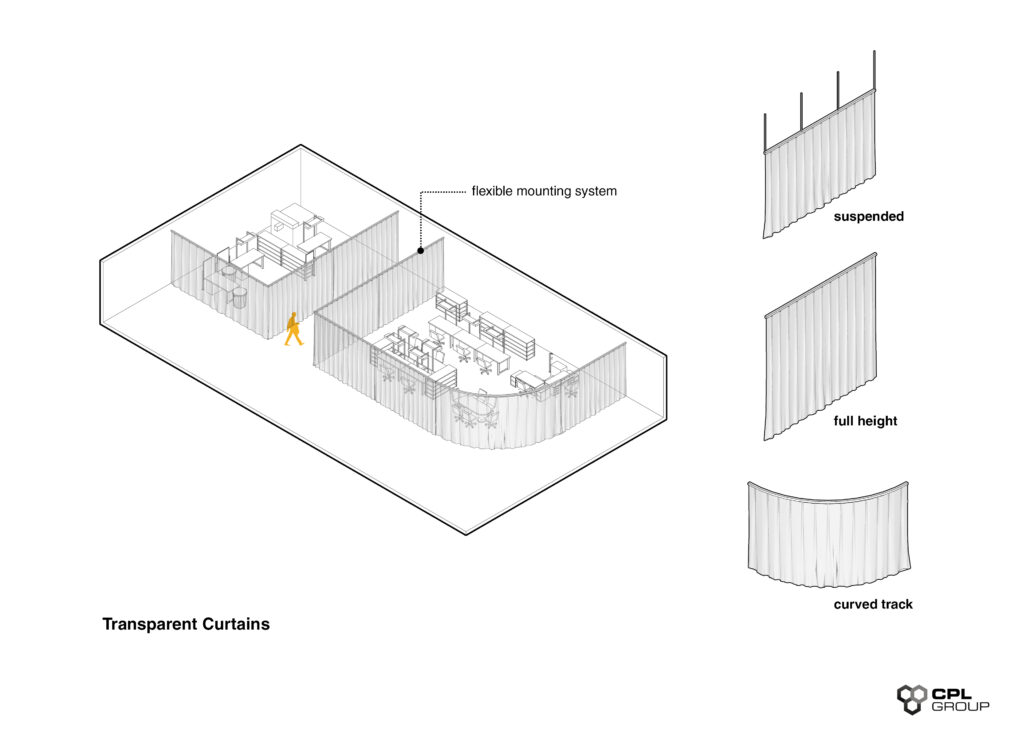

- Custom Curtains and Barriers: Tailored to fit your specific needs, these solutions enhance workflow and safety in your manufacturing processes. Our custom curtains can be designed for various applications, including temperature control, noise reduction, and dust containment.

- Process Optimization Consulting: Our experts provide consulting services to help you identify inefficiencies and implement best practices, improving overall productivity.

Case Study: Boosting Efficiency in a Food Processing Plant

Challenge: A leading food processing plant was struggling with high energy costs and inefficiencies in their production process. They needed a solution to optimize their workflow and reduce operational expenses.

Solution: CPL Group conducted a thorough assessment of the facility and recommended tailored solutions, including the installation of PVC strip curtains for temperature control and the implementation of a streamlined workflow management system.

Results:

- Energy Cost Reduction: The installation of PVC strip curtains helped maintain temperature zones, leading to a 40% reduction in energy costs.

- Increased Production Efficiency: Streamlined workflows and optimized resource utilization resulted in a 20% increase in production efficiency.

- Enhanced Safety: Custom safety barriers and curtains improved the overall safety of the work environment, reducing the risk of accidents.

Key Takeaways – Why Efficiency is the Key

Tailored solutions from CPL Group can transform your manufacturing processes, boosting efficiency and productivity. By focusing on key areas like workflow management, resource utilization, technology integration, and safety enhancements, we help you achieve your operational goals.

Contact us today to learn how we can support your journey towards a more efficient and productive manufacturing operation.