Industrial Safety Curtains: The Ultimate Guide to Clean Zones and Workplace Safety

Why Clean Zones Matter More Than Ever

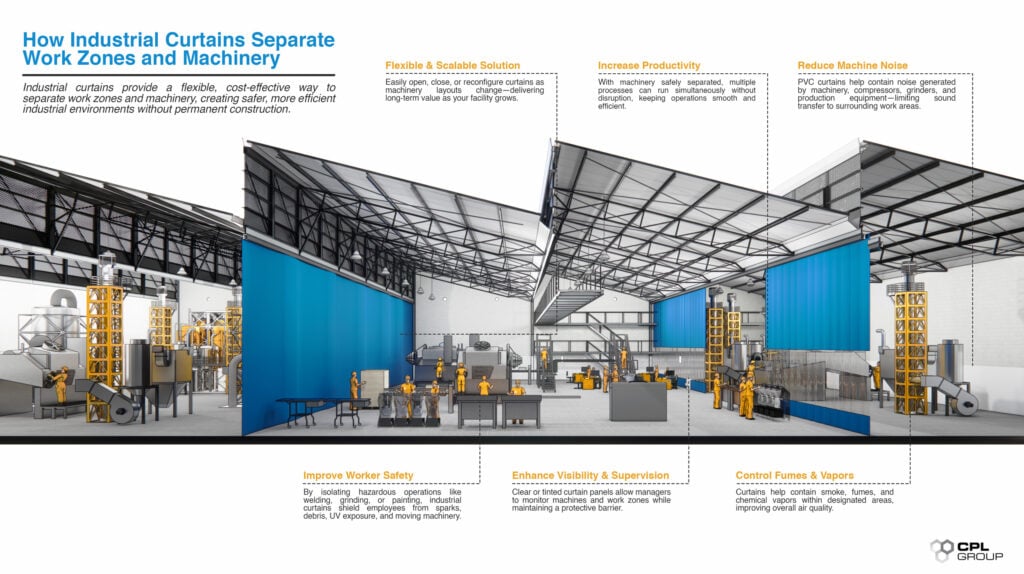

Industrial environments are under increasing pressure to deliver safer, cleaner, and more controlled workspaces. From contamination risks to noise exposure and cross-process interference, unmanaged work floors create inefficiencies and safety hazards.

Industrial safety curtains and PVC screening systems provide a cost-effective, flexible solution — allowing businesses to create defined clean zones without permanent construction.

What Are Industrial Safety Curtains?

Industrial safety curtains are modular PVC-based systems designed to:

- Separate work zones

- Control contaminants

- Reduce noise and airflow interference

- Improve worker safety

👉 Explore PVC screening solutions by CPL Group.

They are widely used in manufacturing, food processing, welding environments, and clean production facilities.

Key Benefits of PVC Screening & Clean Zones

1. Contamination Control

PVC curtains prevent dust, fumes, and airborne particles from spreading between zones.

👉 Learn more about contamination control solutions.

2. Improved Workplace Safety

By isolating hazardous processes, safety curtains help reduce exposure risks and accidents.

3. Noise Reduction

Acoustic PVC systems significantly reduce sound transfer, improving comfort and focus.

👉 View acoustic and noise control systems.

4. Flexible & Cost-Effective Installation

Unlike permanent walls, PVC systems can be installed quickly and adjusted as operations change.

Clean Zones in High-Risk Industries

Manufacturing & Engineering

- Welding curtains

- Machine isolation

- Operator protection

👉 Explore manufacturing industry solutions.

Food & Beverage

- Hygiene zoning

- Wash-down safe curtains

- Cross-contamination prevention

Pharmaceutical & Medical

- Controlled environments

- Compliance-ready partitioning

Choosing the Right Safety Curtain System

Key factors include:

- Curtain thickness and material

- Transparency vs opacity

- Fire resistance

- Wash-down requirements

- Acoustic performance

CPL Group designs bespoke screening systems matched to each environment.

Case-Driven Results: What Businesses Achieve

Clients using CPL Group safety systems report:

- Fewer safety incidents

- Better compliance audit outcomes

- Improved workflow efficiency

- Reduced downtime

Future-Ready Safety & Hygiene Design

As regulations tighten and workforce wellbeing becomes a priority, clean zone design is a strategic investment — not a compliance checkbox.

PVC screening systems allow businesses to:

- Adapt quickly

- Scale safely

- Protect both people and product

👉 Request a workplace safety assessment from CPL Group.

FAQ

What industries use industrial safety curtains?

Manufacturing, food processing, pharmaceuticals, automotive, and logistics all rely on safety curtain systems.

Are PVC curtains compliant with hygiene standards?

Yes — CPL Group’s PVC systems are designed for wash-down environments and regulatory compliance.