Food & Beverage

Our Food & Beverage Industry Products

Flexi Doors

High-Quality and Versatile Flexi Doors for the Manufacturing and Industrial IndustryThese doors are meticulously designed to meet the unique needs of industrial facilities, providing a seamless combination of durability, security, and versatility. Crafted with precision engineering and superior materials, Flexi Doors offer a wide range of features and benefits that cater to the specific demands of industrial environments.

The primary function of CPL Group’s Flexi Doors is to provide reliable and secure access control for industrial settings. These doors are engineered to withstand heavy usage, ensuring smooth and efficient operations within manufacturing facilities. The robust construction and advanced security features make Flexi Doors an ideal choice for protecting valuable assets and maintaining a secure environment.

Robust Construction: Flexi Doors are built with high-quality materials to withstand the demanding conditions of industrial environments. The durable construction ensures long-term performance and resilience against wear and tear.

Customizable Design: These doors are available in a variety of configurations, including sliding, swinging, and folding options, allowing for seamless integration into diverse industrial settings.

Advanced Security Features: With built-in security enhancements such as access control systems, biometric authentication, and reinforced locking mechanisms, Flexi Doors provide unparalleled protection for industrial facilities.

Weather Resistance: Designed to endure extreme weather conditions, Flexi Doors are equipped to maintain functionality and structural integrity in challenging environments.

Optimal Insulation: The doors offer excellent thermal and acoustic insulation, contributing to energy efficiency and a comfortable working environment.

Low Maintenance: Flexi Doors are engineered for minimal maintenance, reducing downtime and operational disruptions.

Enhanced Security: The advanced security features of Flexi Doors provide industrial facilities with a heightened level of protection against unauthorized access and security breaches.

Customization Options: The customizable design allows for tailored solutions that meet the specific requirements of diverse industrial applications.

Longevity and Reliability: The robust construction and durable materials ensure long-term performance and reliability, contributing to cost-effective operations.

Energy Efficiency: The optimal insulation properties of Flexi Doors contribute to energy savings and a controlled internal climate within industrial facilities.

Operational Efficiency: With smooth and reliable operation, Flexi Doors facilitate seamless access control and operational efficiency within industrial environments.

Food Grade Rooms

Food Grade Rooms for the Food & Beverage IndustryAt CPL Group, we offer state-of-the-art Food Grade Rooms tailored to meet the stringent requirements of the Food & Beverage industry. Our Food Grade Rooms are designed to provide a controlled environment for various food processing and storage needs, ensuring compliance with industry regulations and standards.

res Temperature and Humidity Control: Our Food Grade Rooms are equipped with advanced systems to maintain precise temperature and humidity levels, essential for preserving the quality and safety of food products.

Hygienic Design: The rooms are built with materials and surfaces that are easy to clean and maintain, reducing the risk of contamination and ensuring optimal hygiene.

Customizable Configurations: We offer customizable options to suit specific operational needs, including varying sizes, layouts, and storage solutions.

Compliance with Standards: Our Food Grade Rooms adhere to industry-specific standards and regulations, providing peace of mind for businesses in the food and beverage sector.

Enhanced Product Quality: By providing a controlled environment, our Food Grade Rooms help in preserving the freshness and quality of food products, ultimately extending their shelf life.

Regulatory Compliance: Businesses can operate with confidence, knowing that our Food Grade Rooms are designed to meet the strict regulatory requirements of the food and beverage industry.

Operational Efficiency: The customizable configurations allow for efficient utilization of space, streamlined workflows, and optimized storage solutions, contributing to overall operational efficiency.

Food Grade Walls

CPL Group's Food Grade Walls: Elevating Hygiene and Safety in the Food & Beverage IndustryIf you’re seeking a premium-quality solution to ensure hygiene and safety in your food and beverage facility, CPL Group’s Food Grade Walls offer the perfect answer. CPL Group’s Food Grade Walls are designed to provide a hygienic and compliant environment for food and beverage production facilities.

Food-Grade Material: Constructed from food-grade materials, our walls are engineered to meet the stringent requirements of food processing and manufacturing environments

Hygienic Surface: The smooth, non-porous surface prevents the growth of bacteria and mold, ensuring easy cleaning and maintenance of a sanitary environment.

Customizable Options: With a range of colors and finishes available, our food grade walls can be tailored to match your facility’s aesthetic and branding requirements.

Durable and Long-Lasting: Built to withstand the demands of the food and beverage industry, our walls offer long-term durability, reducing the need for frequent maintenance or replacement.

Compliance: Ensure compliance with food safety standards and regulations, providing peace of mind during inspections and audits.

Enhanced Safety: Install walls resistant to moisture, chemicals, and impact, creating a safer environment for food processing and manufacturing.

Cost-Effective: Reduce long-term maintenance costs with our durable and easy-to-clean walls, offering a cost-effective solution for your facility.

Food Storage cool rooms

Food Storage Cool Rooms for the Food & Beverage IndustryAt CPL Group, our Food Storage Cool Rooms are designed to meet the stringent demands of the Food & Beverage industry. These cool rooms provide an optimal solution for preserving perishable goods, maintaining the freshness of food products, and ensuring compliance with industry regulations.

Temperature Control: Our Food Storage Cool Rooms are equipped with advanced temperature control systems to ensure precise regulation of internal conditions, preserving the quality of stored goods.

Spacious Design: With ample storage space, these cool rooms offer the flexibility to accommodate varying inventory sizes, making them ideal for businesses of all scales.

Energy Efficiency: Designed for sustainability, our cool rooms are built with energy-efficient features, helping businesses reduce operational costs while minimizing environmental impact.

Customization Options: We offer customization options to tailor the cool rooms to specific industry requirements, ensuring seamless integration with existing operations.

Extended Shelf Life: By maintaining the optimal storage conditions, our cool rooms help extend the shelf life of perishable goods, reducing waste and improving inventory management.

Compliance Assurance: Businesses can rely on our cool rooms to meet industry standards for food storage, ensuring compliance with regulatory guidelines and maintaining product quality.

Enhanced Operational Efficiency: The efficient design and performance of our cool rooms contribute to streamlined operations, enabling businesses to meet demand with reliable inventory management.

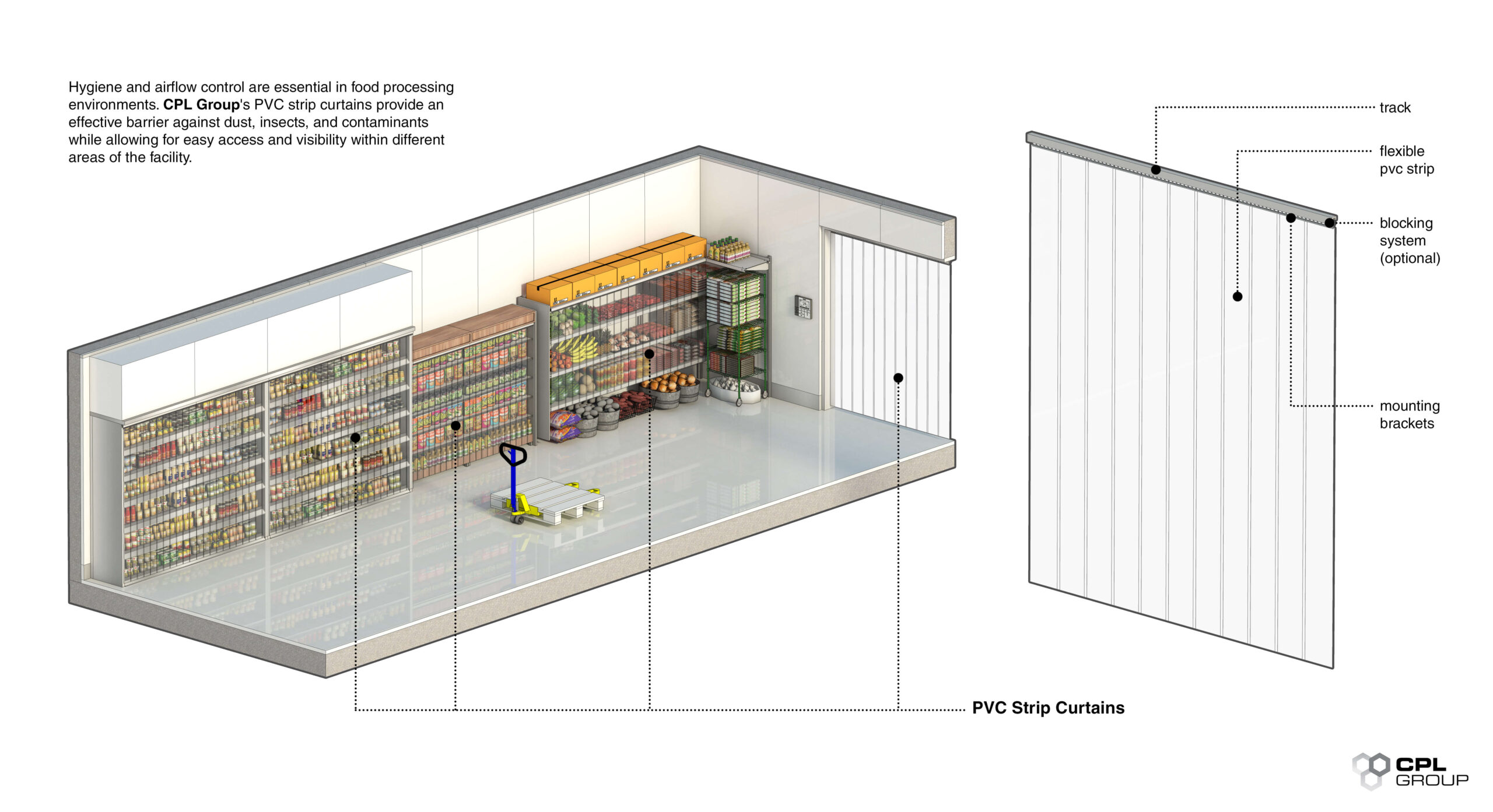

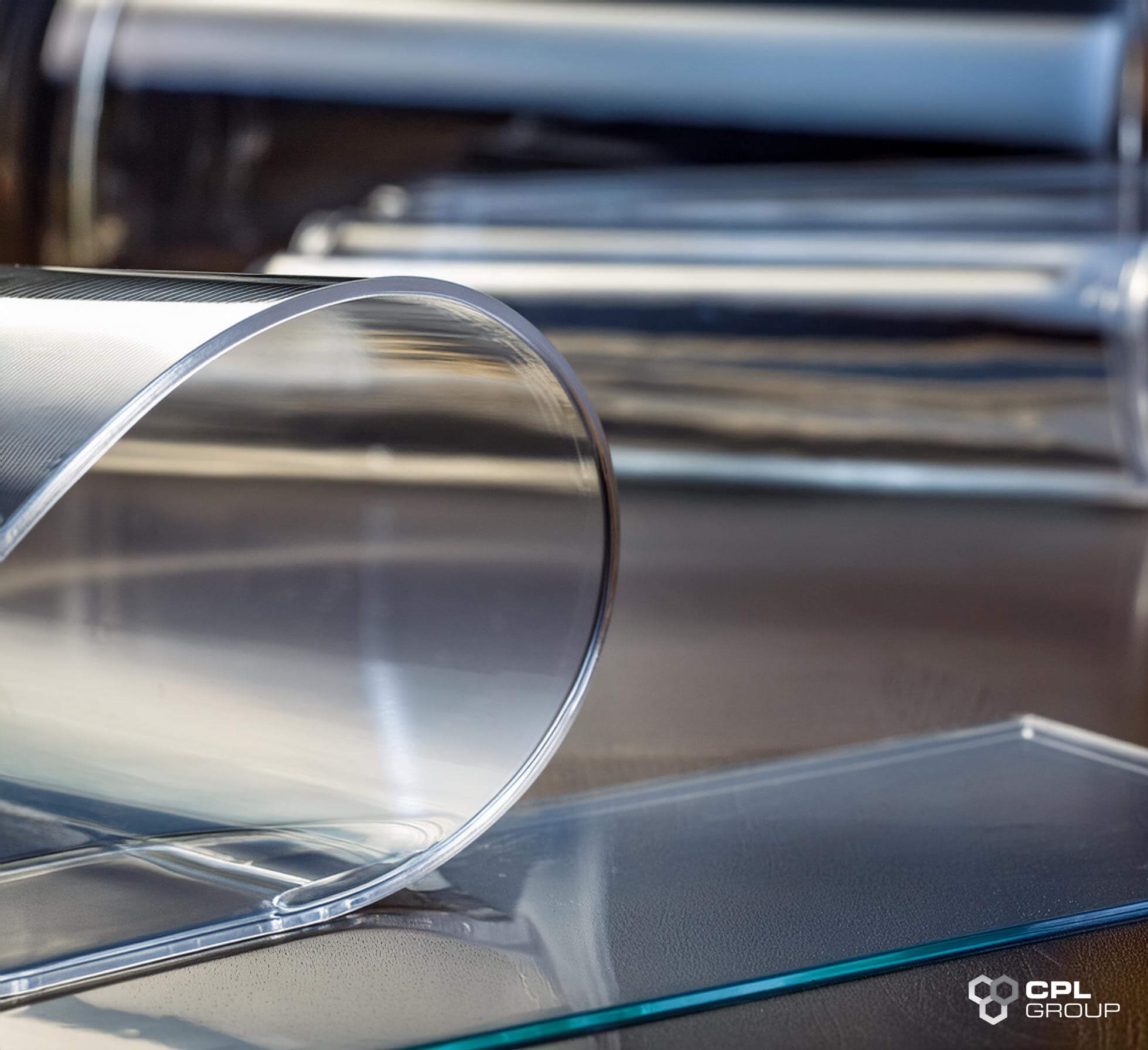

PVC Strip Curtains

Control Hazards and Create Safer, Efficient Spaces with CPL Group's Customizable Strip CurtainsWe specialise in the manufacturing and supply of top-notch, completely customisable Strip Curtains.

Our range of products includes strip curtains, also known as strip doors or flap doors, and strip screen walls, which include strip curtains and sliding screens.

Our strip screen doorways are engineered to provide effective control of workshop hazards, creating safer, more efficient, and organised work environments. They form an efficient barrier against harmful elements such as dust, heat, smoke, fumes, and more, while still allowing easy access.

Easy access for workers and equipment, with the strip curtains, immediately falling back into place

High-quality, durable materials

In-house manufacturing for consistent quality control

A range of colours available, including yellow-tinted insect-repellent PVC and red-tinted glare-reducing PVC for applications such as welding bays

Freezer-grade clear PVC for doorways into freezers or chillers

A variety of thicknesses to suit different applications

Mounting components are made from long-lasting aluminum and stainless steel to prevent corrosion.

f you’re looking for a reliable solution to screen off workshop hazards and create controlled spaces in your facility, our strip curtains are a perfect choice.

Versatility: Our strip curtains can be used on internal or external doors and are suitable for a wide range of applications, including those with high levels of traffic.

Noise reduction: Our curtains help reduce noise levels getting through the door, creating a more peaceful working environment.

Airborne contaminant reduction: Our curtains help reduce pollutants and other airborne contaminants from entering your facility, keeping the air clean and healthy.

Pest prevention: Our curtains prevent insects and rodents from getting through the door, reducing the risk of contamination and damage.

Temperature regulation: Our curtains help regulate temperatures, keeping your facility comfortable and energy-efficient.

Energy savings: The temperature-controlling properties of our plastic door strips help reduce your energy bills, making it an eco-friendly solution.

Customisation: Our curtains can be supplied transparent or with a variety of colours, warning strips, logos, or messages.

Transparency: Our transparent option allows light to pass through while also providing visibility to the other side, a vital safety feature in many environments.

Temperature Control Rooms

Temperature-Controlled Storage Solutions for the Food & Beverage IndustryIn the dynamic landscape of the food and beverage industry, precise temperature control is paramount for preserving the integrity of perishable goods. At CPL Group, our cutting-edge Temperature-Controlled Storage Solutions are meticulously engineered to meet the stringent demands of this sector, ensuring uncompromised freshness and safety throughout the storage and distribution chain.

Customizable Cold Storage: Our temperature-controlled rooms offer customizable sizing, catering to the diverse needs of food processors, distributors, and retailers.

Temperature and Humidity Management: Equipped with advanced systems, our solutions provide precise control over both temperature and humidity, safeguarding the quality of sensitive products.

Energy-Efficient Design: Our storage solutions are designed for energy efficiency, allowing businesses to minimize operational costs without compromising on the maintenance of optimal storage conditions.

Remote Monitoring Capabilities: Integrated with state-of-the-art monitoring technology, our solutions enable remote tracking and management of environmental parameters, ensuring proactive maintenance of ideal storage conditions.

Extended Product Shelf Life: By leveraging our temperature-controlled storage solutions, businesses can extend the shelf life of perishable items, reducing waste and enhancing profitability.

Regulatory Compliance: Our solutions enable businesses to adhere to stringent industry regulations and quality standards, instilling confidence in the safety and integrity of stored products.

Preservation of Freshness: Maintain the freshness and quality of food and beverage products, guaranteeing that they reach end consumers in optimal condition.

Operational Cost Savings: Through energy-efficient design and prolonged product shelf life, our solutions empower businesses to realize significant cost savings and minimize product loss.

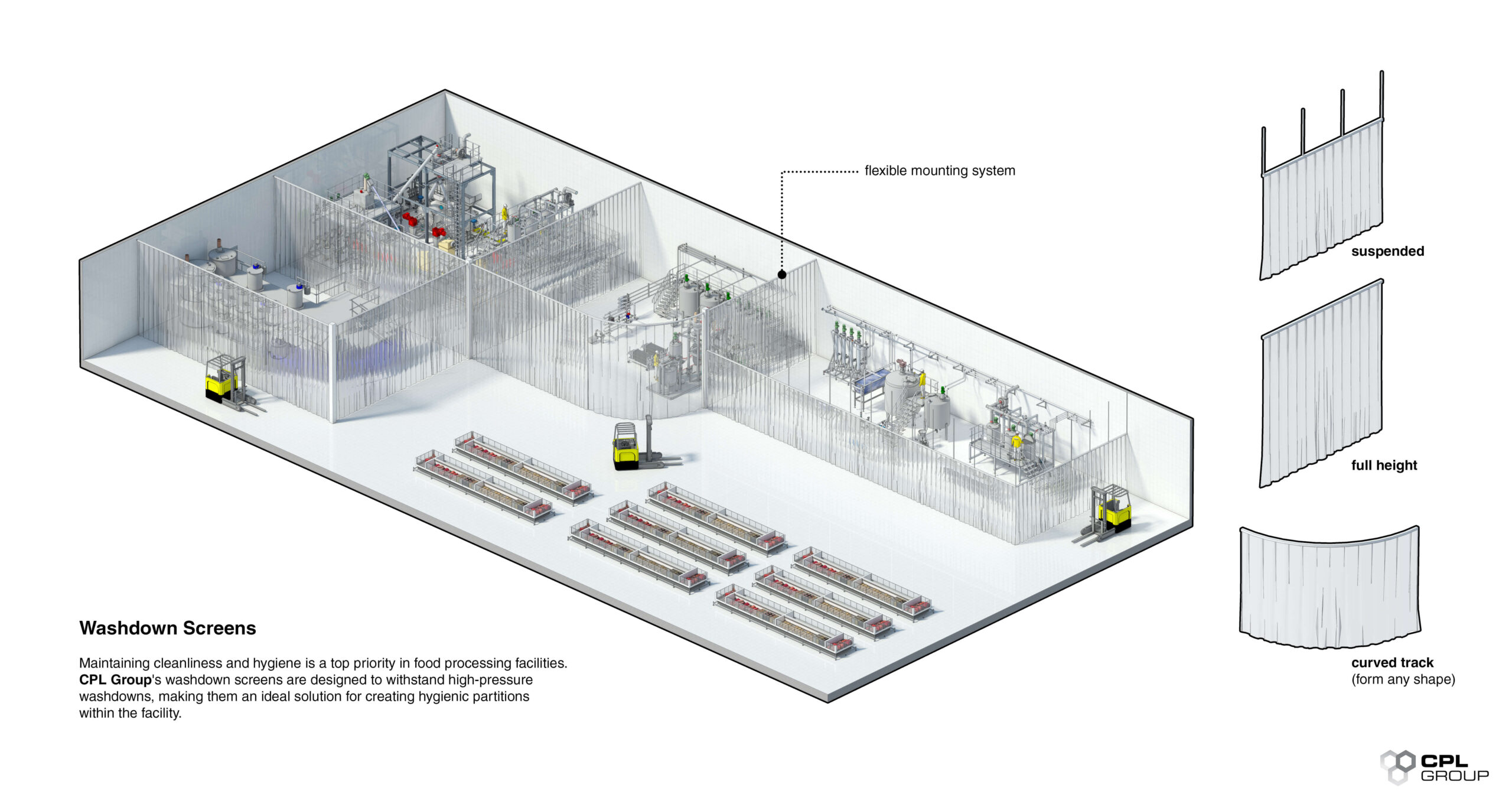

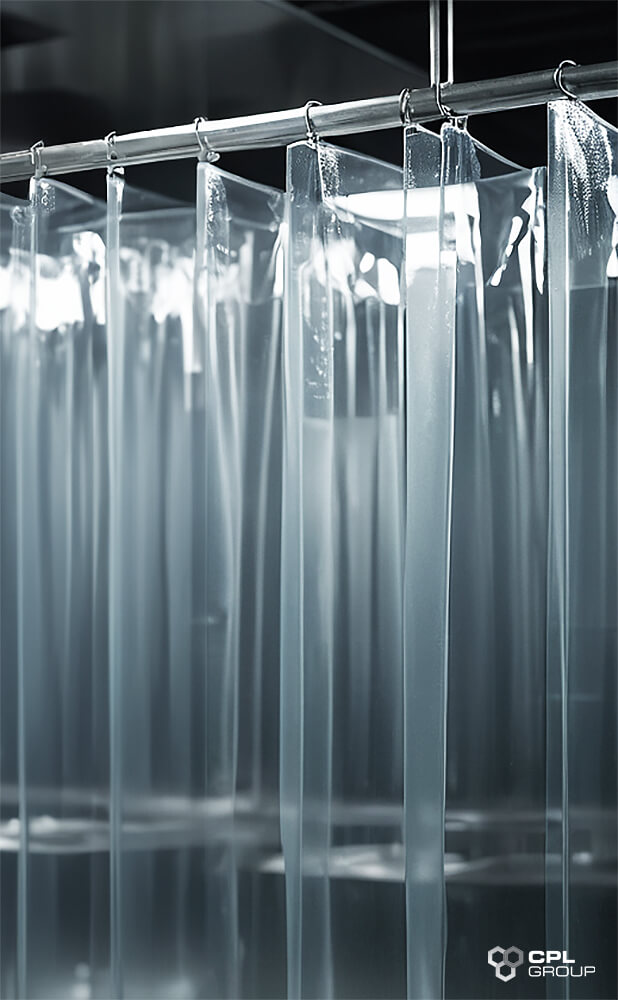

Washdown Screens

High-Performance Washdown Screens for Industrial ManufacturingCPL Group’s high-performance washdown screens are designed to meet the stringent requirements of the manufacturing and industrial industry. These industry-leading screens offer superior protection against contaminants, ensuring a clean and safe working environment for sensitive manufacturing processes. By incorporating essential keywords and highlighting key features and benefits, this SEO-friendly product description aims to optimize the content for search engine visibility and provide valuable information to potential customers.

Enhanced Contaminant Protection: The washdown screens are engineered to provide a robust barrier against dust, debris, and other contaminants, safeguarding sensitive equipment and products from potential damage.

Corrosion-Resistant Construction: Crafted from high-quality, corrosion-resistant materials, these screens offer exceptional durability and longevity, making them ideal for demanding industrial environments.

Easy Maintenance: The screens are designed for easy maintenance, allowing for convenient cleaning and upkeep, thus minimizing downtime and ensuring continuous operational efficiency.

Compliance with Industry Standards: CPL Group’s washdown screens adhere to industry standards and regulations, ensuring that they meet the specific requirements of the manufacturing and industrial sector.

Customizable Options: The screens are available in a range of customizable configurations, allowing for tailored solutions to meet diverse industrial application needs.

Optimal Visibility: With a focus on providing clear visibility and unobstructed views, these screens facilitate efficient monitoring and observation within manufacturing facilities.

Water and Chemical Resistance: The screens are resistant to water and various chemicals, ensuring reliable performance in environments where exposure to liquids and corrosive substances is a concern.

High-Temperature Tolerance: Designed to withstand high temperatures, these screens maintain their integrity and functionality even under extreme thermal conditions.

Versatile Application: Suitable for various industrial settings, including food processing, pharmaceutical manufacturing, electronics assembly, and more, these screens offer versatile solutions for diverse applications.

Improved Workplace Safety: By preventing the ingress of contaminants and ensuring a clean working environment, these screens contribute to enhanced workplace safety and product quality.

Partner with CPL Group for Tailored Aviation Solutions

At CPL Group, we are committed to delivering customised aviation solutions that meet the industry’s exacting standards. Our products are designed to enhance operational efficiency, protect valuable assets, and contribute to a safer and more sustainable aviation environment. With a focus on quality, innovation, and environmental responsibility, we are your trusted partner for comprehensive aviation solutions.

Contact us today to learn more about our Hangar Curtain Doors, Hangar Paint Curtains, and Airport Trolley Covers, and discover how CPL Group can elevate your aviation facility with tailored solutions that make a difference.

Explore our aviation solutions and request a custom quote today to experience the CPL Group advantage.

Client Feedback

We’re collaborators - We build tight-knit partnerships with our clients.

Keep Scrolling

“CPL’s PVC screening solutions have been a game-changer for our facility. The PVC range transformed our work environment into a clean and safe space. The strip screen doors and walls are not only effective but also customizable to our needs. The quality of materials used is evident, and their attention to detail in manufacturing shines through. I highly recommend Duraflex to anyone looking to enhance their workspace.”

Jane M. – Facility Manager

“CPL’s PVC strip screen doors have been a fantastic addition to our restaurant. They’ve helped us maintain a hygienic kitchen environment while allowing easy access for staff. The team at CPL guided us through the customization process, helping us select the right size and color that seamlessly blended with our decor.

Sarah T. – Restaurant Owner

CLIENTS WE WORK WITH

Copyright © 2025