Global Cold Storage Solutions: Enhancing Efficiency in Warehouses and Logistics

In the dynamic world of warehouse and logistics management, one often underestimated facet is the significance of cold storage solutions. Across the globe, where temperature-sensitive goods are abundant, the demand for efficient and compliant cold storage facilities is steadily rising. From fresh produce to pharmaceuticals, maintaining precise temperature control isn’t just a preference but a critical necessity. Our recent blog highlighted how tailored logistics and warehousing solutions help. Let’s explore the global demand, compliance requirements, and industry standards for cold storage solutions in warehouses and logistics facilities worldwide.

The Global Demand for Cold Storage Solutions

The global economy heavily relies on the import and export of perishable goods, pharmaceuticals, and other temperature-sensitive products. With the increasing demand for fresh produce, seafood, dairy, and pharmaceuticals worldwide, there’s a pressing need for reliable cold storage solutions. Warehouses and logistics facilities play a pivotal role in safeguarding the integrity of these products throughout the supply chain. Whether it’s preserving freshness, extending shelf life, or complying with regulatory standards, cold storage is indispensable on a global scale.

Compliance and Regulatory Standards

Compliance with regulatory standards is paramount for cold storage facilities worldwide. Various organizations and regulatory bodies set forth guidelines to ensure the safety and quality of stored goods. These standards encompass the installation, maintenance, and servicing of refrigeration systems, as well as the storage of perishable food items and pharmaceuticals. Adhering to these regulations not only upholds product quality but also mitigates the risks of spoilage and contamination, protecting consumer health on a global level.

Industry Standards and Best Practices for Logistics and Warehousing Facilities

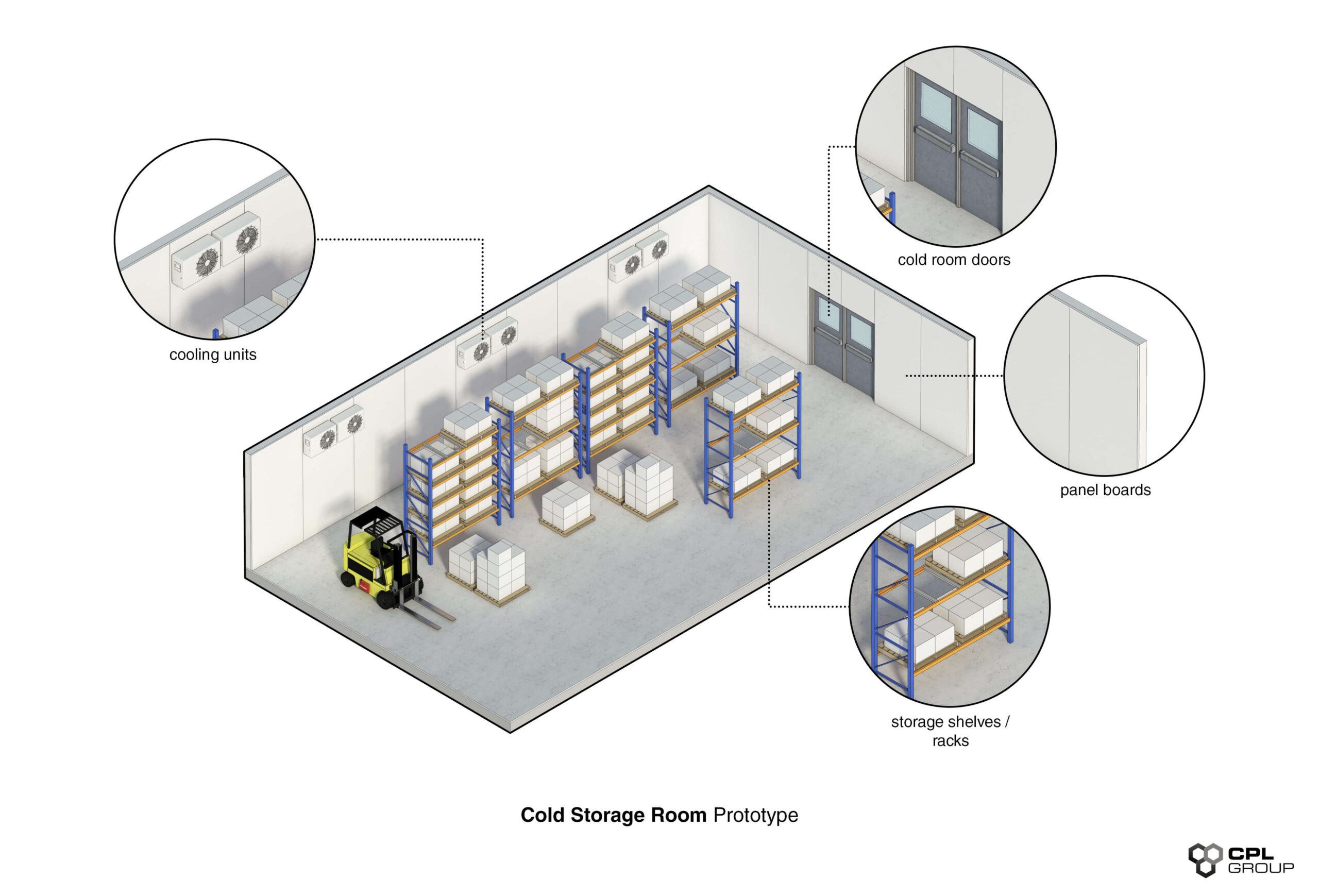

Adhering to industry standards and best practices is essential for effective cold storage management worldwide. Facilities must invest in advanced refrigeration systems capable of maintaining precise temperature and humidity levels. This entails utilizing high-quality insulation materials, environmentally friendly refrigerants, and advanced temperature monitoring technologies. Proper ventilation and airflow management systems are also crucial to prevent temperature fluctuations and ensure uniform cooling throughout the storage facility.

Furthermore, the integration of automated inventory management systems can streamline operations and reduce human error on a global scale. These systems track product movement and monitor temperature variations in real-time, enabling prompt corrective action when deviations occur. Regular maintenance and servicing of refrigeration equipment are equally important to prevent breakdowns and ensure optimal performance, minimizing downtime and operational disruptions.

Innovative Solutions for Cold Storage

As the global demand for cold storage solutions continues to grow, there is a surge in innovative technologies aimed at enhancing efficiency and reliability. Thermal Dividing Walls offer flexibility and scalability to meet evolving storage needs across different regions. These prefabricated units can be swiftly installed and customized to accommodate specific temperature and spatial requirements, making them suitable for facilities worldwide.

Moreover, the integration of IoT (Internet of Things) technology is revolutionizing cold storage management on a global scale. IoT-enabled sensors and devices enable remote monitoring of temperature, humidity, and other environmental factors, providing real-time insights into storage conditions. This not only improves operational efficiency but also enables proactive maintenance and compliance with regulatory standards, ensuring the safety and quality of stored goods across diverse geographical locations.

Key Takeaways

- Cold storage solutions are indispensable for warehouses and logistics facilities worldwide handling temperature-sensitive goods.

- The increasing global demand for fresh produce, pharmaceuticals, and perishable foods underscores the importance of efficient and compliant cold storage infrastructure.

- By adhering to regulatory standards, embracing industry best practices, and adopting innovative technologies, facilities can uphold the integrity and safety of stored goods across the global supply chain.

In an interconnected world, staying ahead in cold storage management is essential for maintaining competitiveness and meeting consumer expectations across diverse markets and regions.