Food Safety and Traceability in the F&B Industry: CPL Group’s Innovative Solutions

In today’s fast-paced food and beverage industry, ensuring food safety and maintaining traceability throughout the supply chain have become paramount concerns. With increasing regulatory pressures and consumer demands for transparency, businesses must adapt and implement robust systems to safeguard their products and reputation. This blog post explores the critical importance of food safety and traceability and how CPL Group’s innovative solutions are helping F&B companies meet these challenges head-on.

The Growing Importance of Food Safety and Traceability

Regulatory Compliance

Recent years have seen a significant tightening of food safety regulations worldwide. The FDA’s Food Safety Modernization Act (FSMA) and the upcoming Food Traceability Final Rule are prime examples of how regulatory bodies are pushing for enhanced traceability and safety measures. These regulations require companies to maintain detailed records of their products’ journey from farm to fork, ensuring quick and efficient recall processes when necessary.

Consumer Trust

Modern consumers are more informed and concerned about the origin and safety of their food than ever before. A single food safety incident can severely damage a brand’s reputation and lead to significant financial losses. By implementing robust traceability systems, companies can not only mitigate risks but also build consumer trust through transparency.

Supply Chain Efficiency

Effective traceability systems do more than just comply with regulations; they can significantly improve supply chain efficiency. By having real-time visibility into product movement and storage conditions, companies can optimize their operations, reduce waste, and improve overall quality control.

CPL Group’s Innovative Solutions for Food Safety and Traceability

At CPL Group, we understand the unique challenges faced by the food and beverage industry. Our comprehensive range of solutions is designed to help businesses enhance their food safety measures and traceability capabilities. Here’s how our products contribute to a safer, more transparent food supply chain:

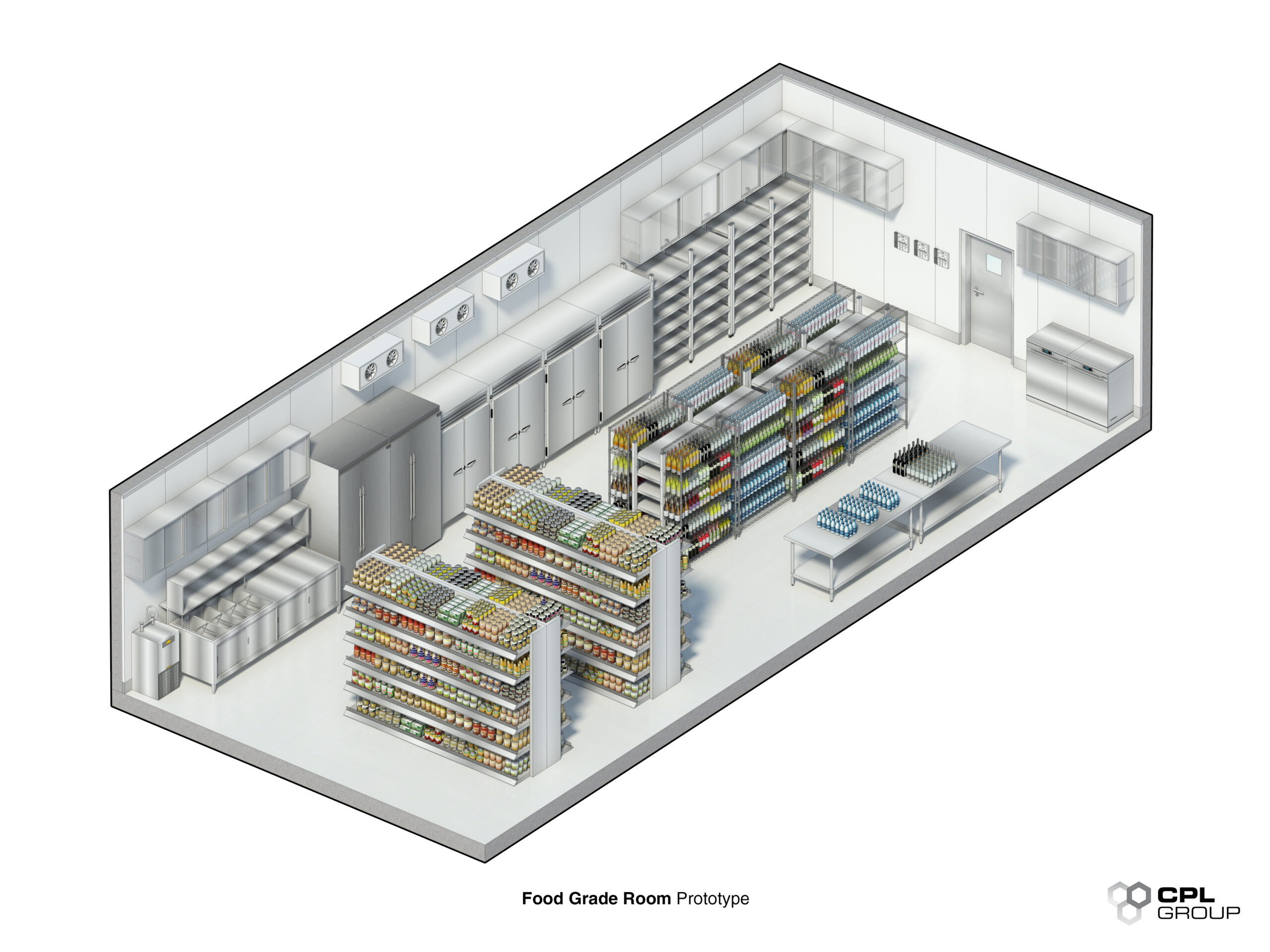

1. Food Grade Rooms

Our state-of-the-art Food Grade Rooms provide a controlled environment crucial for maintaining the highest standards of hygiene and safety in food processing and storage. These rooms are designed to:

- Comply with industry-specific standards and regulations

- Enhance product quality and extend shelf life

- Improve operational efficiency through customizable configurations

2. Food Grade Walls

CPL Group’s Food Grade Walls are engineered to create hygienic and compliant environments for food and beverage production facilities. Key features include:

- Construction from food-grade materials

- Smooth, non-porous surfaces that prevent bacterial growth

- Customizable options to match facility aesthetics and branding requirements

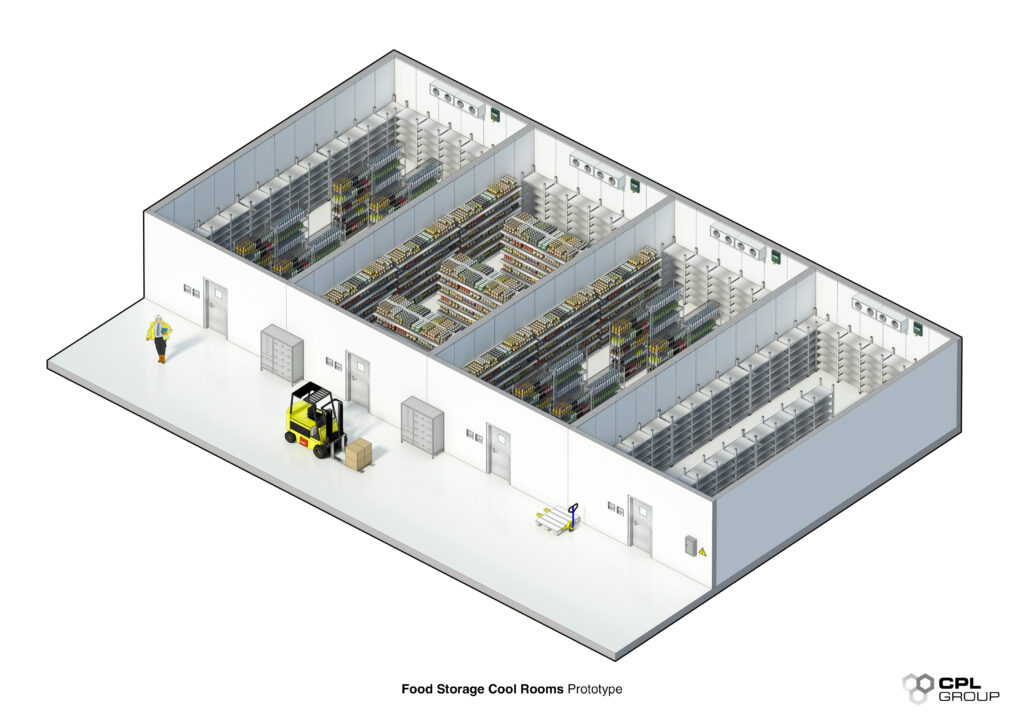

3. Temperature Control Rooms

Our Temperature Control Rooms play a vital role in maintaining the integrity of perishable goods throughout the supply chain. These solutions offer:

- Precise temperature and humidity management

- Energy-efficient design for cost-effective operations

- Remote monitoring capabilities for proactive maintenance

4. Washdown Screens

CPL Group’s Washdown Screens provide superior protection against contaminants in sensitive manufacturing processes. These screens are:

- Constructed from high-durability materials

- Designed for easy cleaning and maintenance

- Ideal for use in processing and packaging areas

Implementing Traceability with CPL Group Solutions

While our physical infrastructure solutions create the foundation for food safety, they also play a crucial role in enhancing traceability:

- Integration with IoT Devices: Our Temperature Control Rooms can be equipped with IoT sensors that continuously monitor and log environmental conditions, creating a digital trail of product storage history.

- QR Code Integration: Food Grade Walls and Rooms can be fitted with QR code systems, allowing for easy tracking of product batches as they move through different processing stages.

- Data Management: By partnering with leading traceability software providers, we ensure that the data collected from our solutions can be seamlessly integrated into comprehensive traceability systems.

As the food and beverage industry continues to evolve, the importance of food safety and traceability will only grow. CPL Group remains committed to innovating and providing cutting-edge solutions that not only meet current regulatory requirements but also prepare businesses for future challenges.

By investing in CPL Group’s comprehensive range of Food and Beverage solutions, companies can enhance their food safety measures, improve traceability, and ultimately build stronger, more resilient businesses. In an industry where trust is everything, let CPL Group be your partner in ensuring the safety and integrity of your products from source to consumer.

Ready to elevate your food safety and traceability capabilities? Contact CPL Group today to learn more about our innovative solutions tailored for the Food and Beverage industry.