Importance of Fume Control Systems in Automotive Workshops

Understanding the technical aspects, compliance requirements, and common challenges of fume control systems can help ensure a safer and more productive work environment. In automotive repair shops, controlling fumes and airborne contaminants is crucial for both worker health and operational efficiency. Fume control systems are designed to address these concerns by providing effective ventilation and filtration.

Tips on the Use and Applications of Fume Control

- Effective Placement:

- Source Capture: Position fume extraction units close to the sources of fumes, such as welding stations, painting areas, and exhaust systems, to capture contaminants at their origin.

- Ventilation Design: Ensure the system’s ductwork and ventilation design are optimized for effective airflow and fume capture.

- Regular Maintenance:

- Filter Replacement: Regularly check and replace filters according to the manufacturer’s guidelines. Clogged or worn-out filters can reduce system efficiency and effectiveness.

- System Inspection: Periodically inspect the entire fume control system, including fans, ducts, and extraction points, to ensure proper operation and address any issues promptly.

- Compliance:

- Regulatory Adherence: Ensure that the fume control system complies with local and national regulations regarding air quality and hazardous emissions. Keep records of maintenance and compliance checks.

- Training: Train staff on the proper use of the fume control system and the importance of maintaining good air quality for health and safety.

- Efficiency:

- Airflow Management: Monitor and adjust airflow rates to ensure optimal performance. Proper airflow helps in effective fume capture and prevents the buildup of contaminants.

- Energy Efficiency: Consider energy-efficient models and practices to reduce operating costs and environmental impact while maintaining effective fume control.

- Safety:

- Emergency Procedures: Develop and communicate emergency procedures for fume control system malfunctions or failures. Ensure that staff are trained to respond to potential hazards.

- Regular Testing: Perform regular testing of the system to verify its performance and ensure it is functioning as intended.

Technical Aspects of Fume Control

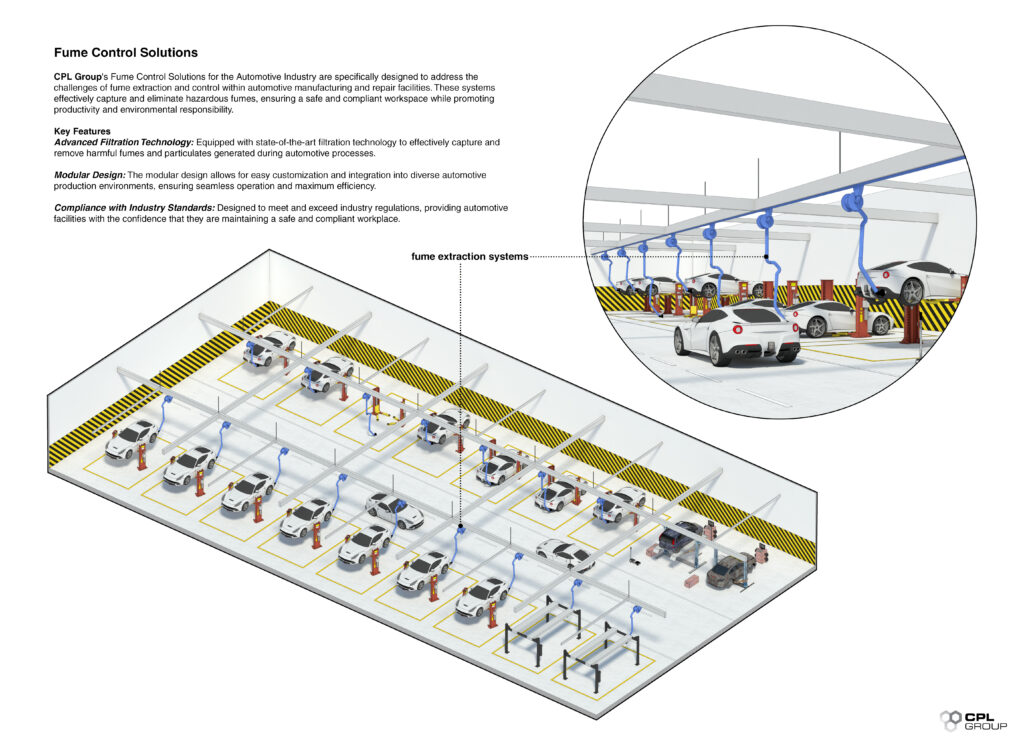

- Ventilation Systems: Fume control systems use advanced ventilation technology to capture and exhaust harmful fumes generated during automotive repair processes. This typically includes localized exhaust systems, such as fume extraction arms and hood systems, which are strategically placed to capture fumes at their source.

- Filtration Technology: These systems often incorporate multi-stage filtration to remove particulates, vapors, and gases. Common filters include HEPA filters for particulates, activated carbon filters for VOCs and odors, and electrostatic precipitators for additional particulate control.

- Airflow Management: Effective fume control requires proper airflow management to ensure that contaminated air is efficiently captured and replaced with clean air. This involves designing systems with adequate airflow rates and ensuring proper placement of extraction units.

Compliance Considerations of Fume Control Systems

- Health and Safety Regulations: Automotive workshops must comply with regulations set by organizations such as OSHA (Occupational Safety and Health Administration) and local environmental agencies. Fume control systems help meet these regulations by reducing exposure to hazardous chemicals and maintaining air quality standards.

- Environmental Regulations: In addition to health and safety compliance, fume control systems must adhere to environmental regulations regarding the discharge of treated air. Systems should be designed to minimize environmental impact and ensure proper handling and disposal of captured contaminants.

Key Problems Solved by Fume Control Systems

- Ineffective Capture: If fume control systems are not properly installed or maintained, they may fail to effectively capture and remove fumes, leading to ongoing health risks and decreased air quality. Regular maintenance and proper system design are essential to prevent this issue.

- Filter Maintenance: Filters in fume control systems need to be regularly inspected and replaced to ensure optimal performance. Neglecting filter maintenance can lead to reduced efficiency and increased operational costs.

- System Cost: High-quality fume control systems can be a significant investment. However, the benefits of improved air quality, compliance with regulations, and enhanced worker safety often outweigh the initial costs. It’s important to consider both the short-term and long-term benefits when evaluating system options.

Fume control systems play a vital role in maintaining a safe and compliant work environment in automotive workshops. By addressing technical, compliance, and maintenance challenges, these systems ensure effective fume capture and air quality management.

Concerned about air quality in your workshop? Contact us to learn more about our fume control systems and how they can improve safety and efficiency in your automotive shop.