The Importance of Cold Chain Management in Safeguarding Food Quality

In the vast landscape of the food and beverage industry, maintaining the quality and safety of perishable goods throughout their journey from production to consumption is paramount. This is where cold chain management steps in as a crucial component ensuring that food products remain fresh, nutritious, and safe for consumers. This week’s blog covers the significance of cold chain management and how implementing temperature-controlled logistics solutions preserves the integrity of food products during transportation and storage.

Understanding Cold Chain Management

Cold chain management is a meticulous process that involves the transportation and storage of perishable goods under controlled temperatures. It encompasses various stages, including harvesting, processing, packaging, transportation, and distribution, all aimed at preserving the freshness and quality of food items. Whether it’s fresh produce, dairy products, meats, or pharmaceuticals, maintaining the cold chain is essential to prevent spoilage, microbial growth, and degradation of product quality.

The Importance of Temperature Control

Temperature control lies at the heart of cold chain management. Fluctuations in temperature can have detrimental effects on perishable goods, leading to spoilage, loss of nutritional value, and potential health hazards. By implementing precise temperature controls at every stage of the supply chain, producers can mitigate these risks and ensure that products reach consumers in optimal condition.

Challenges in Cold Chain Management

Despite its importance, cold chain management poses several challenges. One of the primary concerns is maintaining consistent temperatures

throughout the supply chain, especially during transportation. Factors such as weather conditions, inadequate insulation, equipment malfunctions, and human error can compromise the integrity of the cold chain, leading to costly losses for producers and distributors.

Temperature-Controlled Logistics Solutions

To address these challenges, manufacturers and logistics companies employ a range of temperature-controlled solutions designed to safeguard perishable goods during transit and storage:

1. Refrigerated Trucks and Containers: These specialized vehicles and containers are equipped with refrigeration units that maintain specific temperature settings throughout the transportation process. Whether it’s short-distance deliveries or long-haul shipments, refrigerated transport ensures that products remain within the desired temperature range.

2. Temperature Control Rooms and Systems: Real-time monitoring systems utilize sensors and IoT technology to track temperature variations inside trucks, containers, and storage facilities. These systems provide instant alerts and notifications to operators, allowing them to take corrective actions promptly in case of any deviations from the desired temperature range.

3. Insulated Packaging: Insulated packaging materials, such as thermal liners, insulated containers, and refrigerated pallets, help preserve the cold chain integrity during transit. These packaging solutions minimize heat transfer and protect perishable goods from external temperature fluctuations, ensuring their freshness upon arrival.

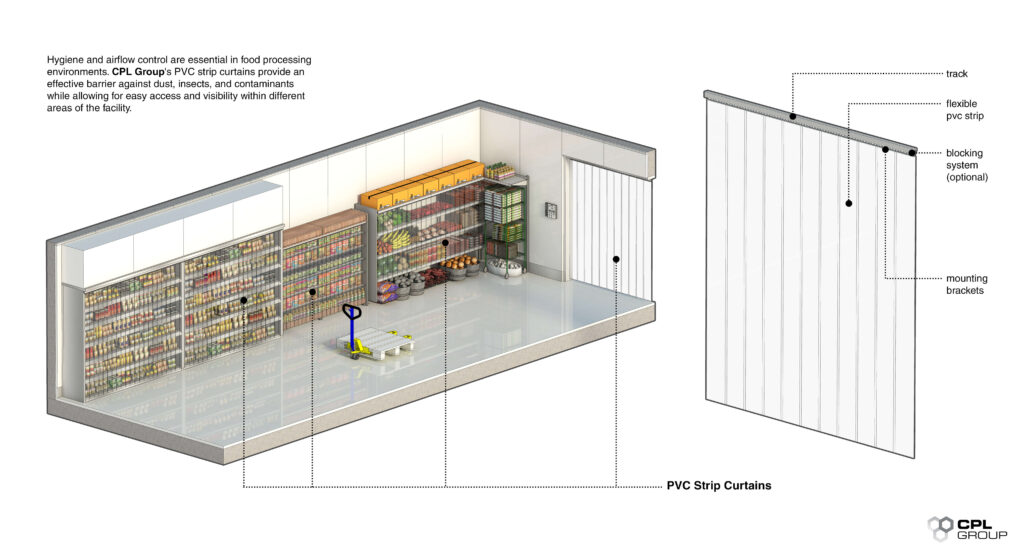

4. Food Storage Cool Rooms: Temperature-controlled warehouses and storage facilities play a critical role in cold chain management. These facilities are equipped with refrigeration units, humidity controls, and monitoring systems to maintain ideal storage conditions for various types of perishable goods.

5. Advanced Refrigeration Technology: Innovative refrigeration systems, such as blast freezers, cryogenic cooling, and vacuum cooling, offer efficient cooling solutions for rapidly chilling or freezing food products. These technologies help reduce processing time, minimize energy consumption, and preserve the quality of perishable goods.

Benefits of Cold Chain Management

Implementing effective cold chain management offers numerous benefits for producers, distributors, retailers, and consumers alike:

6. Quality Assurance: By maintaining the integrity of the cold chain, producers can ensure that their products retain their freshness, flavor, and nutritional value, enhancing consumer satisfaction and loyalty.

7. Extended Shelf Life: Proper temperature control helps extend the shelf life of perishable goods, reducing waste and maximizing profitability for businesses.

8. Compliance with Regulations: Cold chain management is essential for complying with regulatory standards and food safety requirements imposed by government agencies and industry associations.

9. Market Expansion: Reliable cold chain infrastructure enables producers to access new markets and export opportunities, catering to diverse consumer demands worldwide.

Why it matters

Cold chain management plays a pivotal role in safeguarding the quality and safety of perishable goods throughout the supply chain. By implementing temperature-controlled logistics solutions and adhering to best practices in cold chain management, producers can ensure that their products reach consumers in pristine condition, thereby fostering trust, loyalty, and long-term success in the food industry. Investing in cold chain infrastructure is not just a necessity but a strategic imperative for businesses seeking to thrive in an increasingly competitive market landscape.