Floating Silt Curtains & Sediment Control Barriers

As a crucial element of environmental protection in New Zealand, CPL Group’s sediment control products are designed to effectively manage and contain sediment and silt during various offshore and nearshore operations.

Our products play a vital role in minimising the ecological impact of industrial activities in the marine and coastal areas of New Zealand. They are constructed using the highest grade materials and serve as effective barriers in calm water environments, such as aquatic ponds, rivers, estuaries, and open water conditions, to control suspended solids and settle silt releases.

Contact CPL Group today to book an order.

Sediment Control

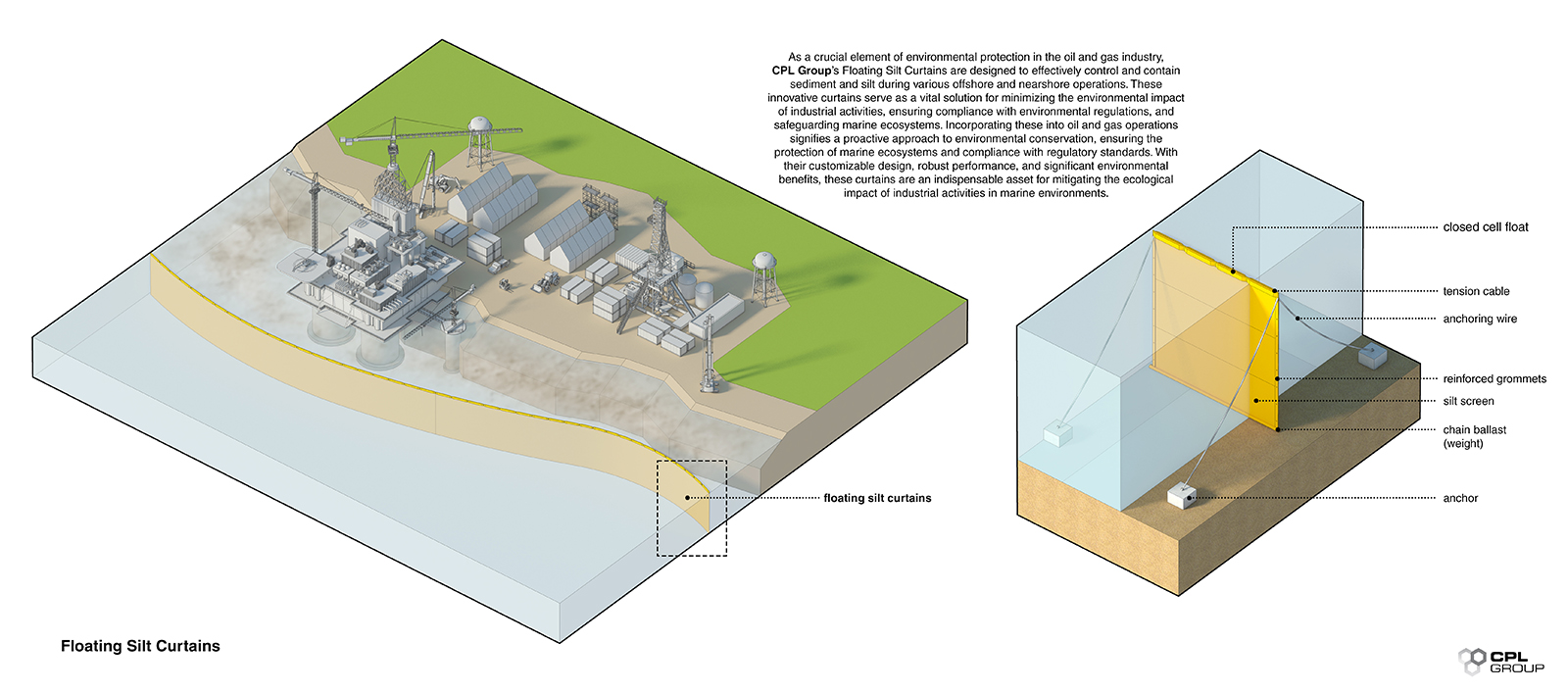

As a crucial element of environmental protection in the oil and gas industry, CPL Group’s Floating Silt Curtains are designed to effectively control and contain sediment and silt during various offshore and nearshore operations.

These innovative curtains serve as a vital solution for minimizing the environmental impact of industrial activities, ensuring compliance with environmental regulations, and safeguarding marine ecosystems.

Incorporating these high-quality Silt Curtains from CPL Group into oil and gas operations signifies a proactive approach to environmental conservation, ensuring the protection of marine ecosystems and compliance with regulatory standards.

With their customizable design, robust performance, and significant environmental benefits, these curtains are an indispensable asset for mitigating the ecological impact of industrial activities in marine environments.

High-Performance Material: Constructed from durable and environmentally friendly materials, CPL Group’s Floating Silt Curtains are engineered to withstand harsh marine conditions and provide long-lasting performance.

Customizable Design: Tailored to meet specific project requirements, these curtains come in a variety of sizes and configurations, allowing for seamless integration into diverse marine environments and operational scenarios.

Efficient Sediment Containment: The innovative design of the curtains effectively traps and contains sediment and silt, preventing their dispersion into surrounding water bodies and minimizing ecological disturbance.

Versatile Deployment: Suitable for a wide range of applications, including dredging, construction, and maintenance projects, the curtains offer versatile deployment options to address varying operational needs.

Environmental Compliance: Designed following industry best practices and environmental guidelines, the silt curtains ensure adherence to stringent regulatory standards and promote sustainable operational practices.

Environmental Protection: By minimizing sediment dispersion, the curtains help protect marine ecosystems and maintain water quality, contributing to sustainable environmental stewardship.

Regulatory Compliance: Utilizing CPL Group’s Floating Silt Curtains aids in compliance with environmental regulations and permits, mitigating potential legal and financial liabilities.

Operational Efficiency: The efficient containment of sediment enhances operational efficiency by reducing the need for cleanup and minimizing disruptions to ongoing activities.

Cost Savings: By preventing sediment migration and minimizing environmental impact, the curtains help avoid costly fines, remediation efforts, and project delays.

Enhanced Corporate Responsibility: Incorporating these curtains into oil and gas operations demonstrates a commitment to environmental responsibility and sustainable business practices, enhancing corporate reputation.

What Are Floating Silt Curtains and Why Are They Used?

Floating silt curtains, also known as turbidity curtains, are specialised barriers designed to contain and control the spread of sediment, silt, and other particulates in water bodies during construction, dredging, and other industrial activities. These curtains float on the water’s surface and are anchored to the bottom, creating a vertical barrier that prevents suspended solids from spreading beyond the work area.

Industrial activities in marine and coastal areas often disturb sediment on the seabed which can lead to high turbidity levels that can have several negative environmental impacts. Sediment dispersion can smother marine habitats, harm aquatic life, and disrupt ecosystems. Increased turbidity reduces light penetration, affecting photosynthesis in aquatic plants and harming fish and other marine organisms.

Furthermore, suspended sediments can carry pollutants and nutrients, which degrade water quality and can lead to issues such as algal blooms. Many industrial activities are subject to strict environmental regulations that limit the amount of sediment and turbidity allowed in water bodies. Failing to control sediment dispersion can result in legal and financial penalties. Therefore, oil, gas, and water industries use sediment control barrier and oil spill containment New Zealand to prevent environmental pollution.

Our floating silt curtains effectively contain sediment and prevent it from spreading beyond the designated work area. They help maintain water clarity and quality, preserving the health of ecosystems. Our silt curtains can help industries comply with environmental regulations regarding turbidity levels and sediment control NZ. This reduces the risk of fines and legal actions.

Industrial Use Cases of Our Sediment Control Product

Our floating silt curtains can be used in marine and coastal construction projects, such as building bridges, piers, and seawalls, for sediment control and protection of water quality.

They are also deployed during offshore drilling and pipeline installation to prevent sediment disturbance and protect marine ecosystems.

In mining operations, they can be used near water bodies to contain sediment runoff, maintain water quality, and minimise environmental impact.

If your industry requires our silt curtains to meet regulatory standards and enhance operational efficiency, contact CPL Group today.

We’ll customise our products to meet your project requirements and ship them as soon as possible.

How to Install Floating Silt Curtains

Installing floating silt curtains correctly is crucial for an effective sediment control system and environmental protection. Start by conducting a thorough assessment of the installation site to understand water depth, current velocity, wind conditions, and the extent of the area to be enclosed.

- Choose a silt curtain suitable for your project based on water conditions, type of sedimentation, and project duration. Ensure the curtain length, depth, and materials match the specific requirements of the site.

- Use buoys or markers to delineate the area where the pollution prevention product will be installed.

- Determine the optimal path for deploying the silt curtain, taking into account water currents and wind direction to minimise resistance during installation.

- Place the anchors at predetermined intervals along the deployment path.

- From a deployment boat, carefully unroll the silt curtain on the water surface, ensuring it remains flat and free of tangles.

- Attach the flotation devices to the top of the curtain and weights to the bottom. Ensure the curtain hangs vertically in the water, creating an effective barrier from surface to seabed.

- Attach the curtain to the anchors using ropes or cables for a tight and secure connection.

- Once the curtain is in place, make any necessary adjustments to ensure it is properly positioned and tensioned. Make sure there are no gaps where sediment could escape.

Maintenance Tips

Periodically inspect the silt curtain for damage, such as tears or abrasions. Repair or replace damaged sections promptly to ensure continued effectiveness. If water conditions change significantly (e.g., increased current velocity or wave height), adjust the curtain setup to maintain its stability and effectiveness.

Frequently Asked Questions

Sediment control and erosion control are related concepts but they are not exactly the same thing. Erosion control is primarily focused on preventing the detachment of soil particles, while sediment control aims to capture and manage those particles once they have been eroded.

Erosion control measures are often implemented on the soil surface and slopes, whereas sediment control measures are typically installed in areas where water collects, such as ditches, ponds, and streams. Erosion control is the first line of defence to keep soil in place, followed by sediment control measures to capture any soil that does become dislodged.

To determine which silt curtain is best for your project, consider the specific requirements of the site and the work to be done along the seabed. Silt curtains deflect water towards the bottom, carrying suspended particles with it.

Consider these factors:

- How long will the curtain be in the water?

- Is the site exposed to tidal movements? How will larger tides affect the curtains?

- What is the depth of the water at the site?

- Is the riverbed or seafloor made of sand, dirt/mud, or rock?

- What buoyant force and ballast requirements are necessary for effective results?

- What machinery and equipment will be operating?

- Will you need a directional type anchor system or an embedment style anchor system?

- Consider the impact on the safety of marine animals.

Yes, silt curtains can be reused in some circumstances. They must be cleaned before storage, and storage requirements may vary based on your specific product. If unsure, please speak with us first.

here is no difference between the two; they are the same product. Silt curtains are often referred to as silt booms or turbidity curtains.

CLIENTS WE WORK WITH

Copyright © 2026