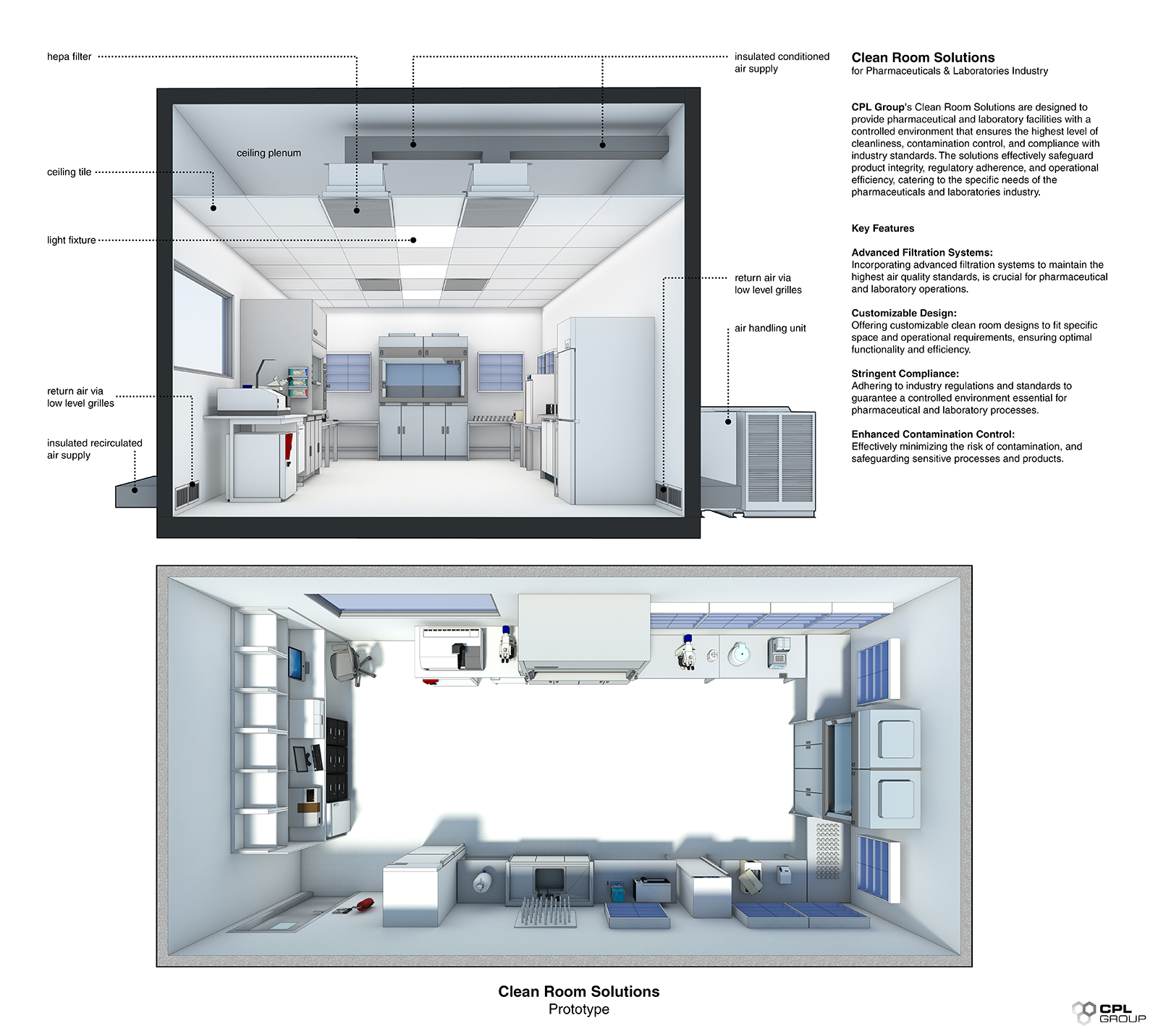

Clean Room Solutions for the Pharmaceuticals and Laboratories Industry

CPL Group specialises in providing pharmaceutical clean room solutions engineered using modern technology to meet the stringent requirements of pharmaceutical and laboratory environments. Our solutions are purpose-built and have advanced filtration systems to ensure a controlled environment essential for pharmaceutical and laboratory processes.

Pharmaceutical Clean

Pharmaceutical Clean Rooms

CPL Group specializes in providing tailored Clean Room Solutions designed specifically for the Pharmaceuticals and Laboratories industry. These cutting-edge solutions are equipped with state-of-the-art technology to meet the stringent requirements of pharmaceutical and laboratory environments.

Purpose and Function

- CPL Group's Clean Room Solutions are purpose-built to provide pharmaceutical and laboratory facilities with a controlled environment that ensures the highest level of cleanliness, contamination control, and compliance with industry standards.

- The solutions effectively safeguard product integrity, regulatory adherence, and operational efficiency, catering to the specific needs of the Pharmaceuticals and Laboratories industry.

Advanced Filtration Systems: Incorporating advanced filtration systems to maintain the highest air quality standards, is crucial for pharmaceutical and laboratory operations.

Customizable Design: Offering customizable clean room designs to fit specific space and operational requirements, ensuring optimal functionality and efficiency.

Stringent Compliance: Adhering to industry regulations and standards to guarantee a controlled environment essential for pharmaceutical and laboratory processes.

Enhanced Contamination Control: Effectively minimizing the risk of contamination, and safeguarding sensitive processes and products.

Regulatory Compliance: Ensuring compliance with industry regulations and standards, fostering trust and reliability in pharmaceutical and laboratory operations.

Product Integrity: Maintaining the integrity of pharmaceutical products and laboratory experiments by minimizing the risk of contamination.

Operational Efficiency: Optimizing operational efficiency with customizable designs that cater to the unique needs of pharmaceutical and laboratory facilities.

Enhanced Cleanliness: Creating an environment of the highest cleanliness standards, vital for the precision and accuracy of pharmaceutical and laboratory processes.

What Are Pharmaceutical Clean Rooms?

Pharmaceutical cleanrooms are specialised environments designed to maintain strict control over air quality, temperature, humidity, and contamination levels. These solutions are essential in pharmaceutical industries where maintaining a sterile environment is critical for product safety, efficacy, and compliance with regulatory standards.

They are equipped with advanced filtration systems and airlocks that minimise the risk of contamination from airborne particles, microorganisms, and other pollutants. This ensures that pharmaceutical products are manufactured in a controlled environment, reducing the risk of product recalls and ensuring patient safety.

Our solutions can also provide a controlled setting for research and development activities without the interference of external contaminants. This is vital for the development of new drugs and therapies.

Key Features of CPL Group’s Pharmaceutical Cleanrooms

Designing an effective clean room solution requires meticulous planning and attention to detail to ensure the highest standards of cleanliness, contamination control, operational efficiency, and regulatory requirements.

Several key considerations must be taken into account to create an optimal environment for pharmaceutical and laboratory operations. Our team takes into account all vital factors to design tailored clean room solutions for our clients.

HEPA Filters

Maintaining the highest standards of air quality is essential for pharmaceutical and laboratory environments. Our clean rooms incorporate High-efficiency particulate air (HEPA) filters that can remove 99.97% of airborne particles that are 0.3 microns or larger. This helps maintain a contamination-free environment.

Insulated Conditioned Air Supply

This system ensures precise control over temperature and humidity levels necessary to maintain the integrity of sensitive processes and products. We use advanced insulated conditioned air supply systems to regulate temperature levels efficiently.

Ceiling Plenum and Tiles

The ceiling plenum is used to evenly distribute air throughout the clean room, maintaining consistent pressure and flow to prevent contamination. While our ceiling tiles are easy to clean and resistant to microbial growth, helping maintain strict cleanliness standards.

Light Fixtures

Adequate lighting is essential for operational efficiency and safety. Our clean rooms include light fixtures that provide adequate lighting while minimising particle generation to ensure a safe and efficient working environment.

Return Air via Low-Level Grilles

Managing return air is crucial in clean rooms to ensure optimal air quality and contamination control. We use two low-level grilles in the room to effectively capture and remove contaminated air from lower areas. This approach supports a downward airflow pattern, pushing contaminants away from critical work areas and ensuring a more sterile setting. By maintaining balanced pressure and efficient ventilation, low-level return air grilles help meet stringent regulatory standards and contribute to the overall effectiveness and energy efficiency of the clean room.

Air Handling Unit

An efficient air handling unit is necessary to manage the supply and return of air. This unit supports both insulated conditioned air supply and recirculated air supply to maintain optimal environmental conditions.

Use Cases of Pharma Cleanroom

Cleanroom solutions have a profound impact on pharmaceutical production[internal link: pharmaceutical production] as they minimise the risk of contamination, which is critical for the production of sterile drugs and sensitive research activities. These environments enable consistent and reliable conditions, reducing the variability that can affect experimental outcomes and product quality.

In pharmaceutical manufacturing, clean rooms are used to produce sterile drugs, including injectables, vaccines, and biologics, where even the smallest contamination can compromise product safety and efficacy.

In the biotechnology industry, these ISO certified rooms provide the controlled environment necessary for manipulating and culturing cells and genes without the risk of contamination. Additionally, the production of biopharmaceuticals, such as monoclonal antibodies and recombinant proteins, demands a sterile environment to maintain product purity and quality.

- Facilities conducting clinical trials use clean rooms to prepare and handle investigational drugs, ensuring that trial results are not compromised by contaminants.

- Manufacturing environments for medical implants and prosthetics require these rooms to prevent microbial contamination that could lead to infections post-implantation.

- The production of diagnostic tools and equipment, such as blood analyzers and imaging devices, uses clean rooms to maintain high standards of hygiene and functionality.

- Clean rooms are also essential for the production of nutraceuticals, which require high standards of cleanliness to ensure product safety and efficacy.

- Food testing laboratories use these specialised rooms to maintain the integrity of samples during microbial and chemical analysis.

Build Your Personalised Clean Room Today

Want to build a personalised clean room for your industry? Contact us today to discuss your unique requirements, and we will customise our design to meet your operational needs. Our primary goal is to ensure that pharmaceutical industries always meet health and safety guidelines because what they produce saves lives, and we can’t compromise on that.

CLIENTS WE WORK WITH

Copyright © 2026