Industrial Thermal Solutions for Smarter Cold Chain Efficiency in 2026

Why Thermal Efficiency Is Now a Competitive Advantage

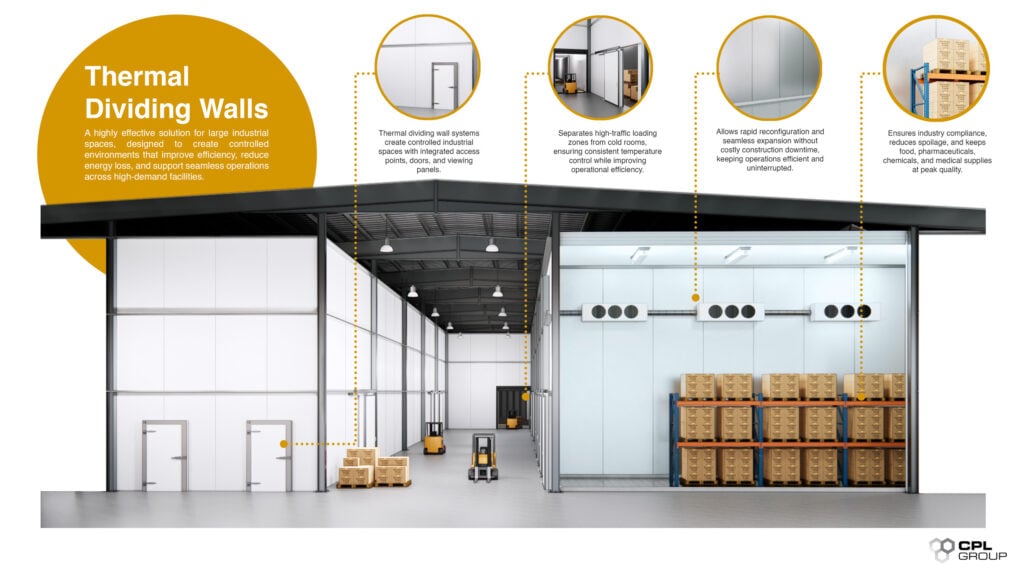

Energy costs, sustainability targets, and supply chain pressures are forcing industrial operators to rethink how temperature-controlled environments are designed. In cold storage facilities, warehouses, and manufacturing plants, inefficient thermal control isn’t just expensive — it directly impacts productivity, compliance, and product integrity.

Modern industrial thermal solutions are no longer static walls or outdated insulation methods. They are flexible, modular systems designed to adapt to workflow changes while delivering measurable efficiency gains.This is where CPL Group’s thermal and cold chain solutions play a critical role — helping businesses reduce energy waste, improve operational flow, and protect temperature-sensitive goods at scale.

The Hidden Cost of Poor Temperature Control in Industrial Facilities

Many facilities lose significant energy through:

- Poorly insulated zones

- Constant door openings between temperature areas

- Inflexible wall systems that don’t adapt to workflow changes

- Air leakage between ambient and cold environments

These issues lead to:

- Increased refrigeration load

- Higher energy bills

- Condensation and moisture problems

- Reduced product shelf life

- Uncomfortable and unsafe working conditions

According to industry studies, inefficient thermal zoning can increase cold storage energy usage by up to 30%.

What Are Smart Thermal Solutions?

Smart thermal solutions focus on controlling air movement, separating temperature zones, and adapting to operational demands without disrupting workflow.

At CPL Group, this includes systems such as:

- Thermal Dividing Walls

- Insulated PVC Strip Curtains

- Rapid Access Thermal Doors

- Modular Cold Storage Enclosures

👉 Explore CPL Group’s thermal dividing wall systems.

These systems create controlled environments without permanent construction, allowing facilities to scale or reconfigure as needs evolve.

Key Benefits of CPL Group Thermal Solutions

1. Significant Energy Savings

By reducing cold air loss and limiting thermal transfer, facilities can lower refrigeration demand and achieve measurable reductions in energy consumption.

👉 Learn more about energy-efficient industrial solutions.

2. Improved Cold Chain Integrity

Maintaining consistent temperatures protects product quality, especially for:

- Food & beverage

- Pharmaceuticals

- Chemicals

- Medical supplies

Thermal separation ensures compliance with industry standards and reduces spoilage risk.

3. Operational Flexibility

Unlike fixed walls, modular thermal systems allow:

- Rapid reconfiguration

- Expansion without construction downtime

- Seasonal workflow adjustments

This flexibility is especially valuable in high-throughput logistics environments.

4. Enhanced Worker Comfort & Safety

Controlled temperatures improve working conditions, reduce condensation, and lower slip hazards — leading to better productivity and fewer incidents.

Thermal Dividing Walls: The Backbone of Modern Cold Chain Design

One of the most effective solutions for large industrial spaces is thermal dividing wall systems.

These walls:

- Separate temperature zones efficiently

- Maintain insulation performance

- Allow fast installation with minimal disruption

- Can integrate access points, doors, and viewing panels

👉 View CPL Group’s industrial wall and partition solutions.

They are ideal for warehouses managing multiple temperature ranges within a single footprint.

Real-World Applications Across Industries

Logistics & Warehousing

- Creating chilled picking zones

- Isolating loading bays

- Reducing cold air loss during loading cycles

Food Processing

- Segregating raw and cooked areas

- Maintaining hygiene and temperature compliance

👉 See CPL Group’s food industry solutions.

Pharmaceuticals

- Temperature-controlled storage

- Clean and compliant production areas

Key Considerations When Upgrading Thermal Systems

Before investing in thermal upgrades, businesses should assess:

- Temperature differentials between zones

- Frequency of access between areas

- Insulation performance (U-values)

- Energy usage patterns

- Future scalability needs

CPL Group works directly with clients to design tailored thermal solutions that align with both operational and sustainability goals.

Future-Proofing Your Facility for 2026 and Beyond

As energy regulations tighten and operational efficiency becomes a competitive differentiator, smart thermal solutions are no longer optional.

Facilities that invest now benefit from:

- Reduced operating costs

- Improved compliance

- Better working environments

- Increased long-term resilience

👉 Request a thermal efficiency assessment from CPL Group.

FAQ

What are thermal dividing walls?

Thermal dividing walls are insulated partition systems designed to separate temperature zones within industrial facilities while minimizing air leakage and energy loss.

How do thermal solutions reduce energy costs?

By limiting air exchange and improving insulation, thermal systems reduce refrigeration load and lower overall energy consumption.