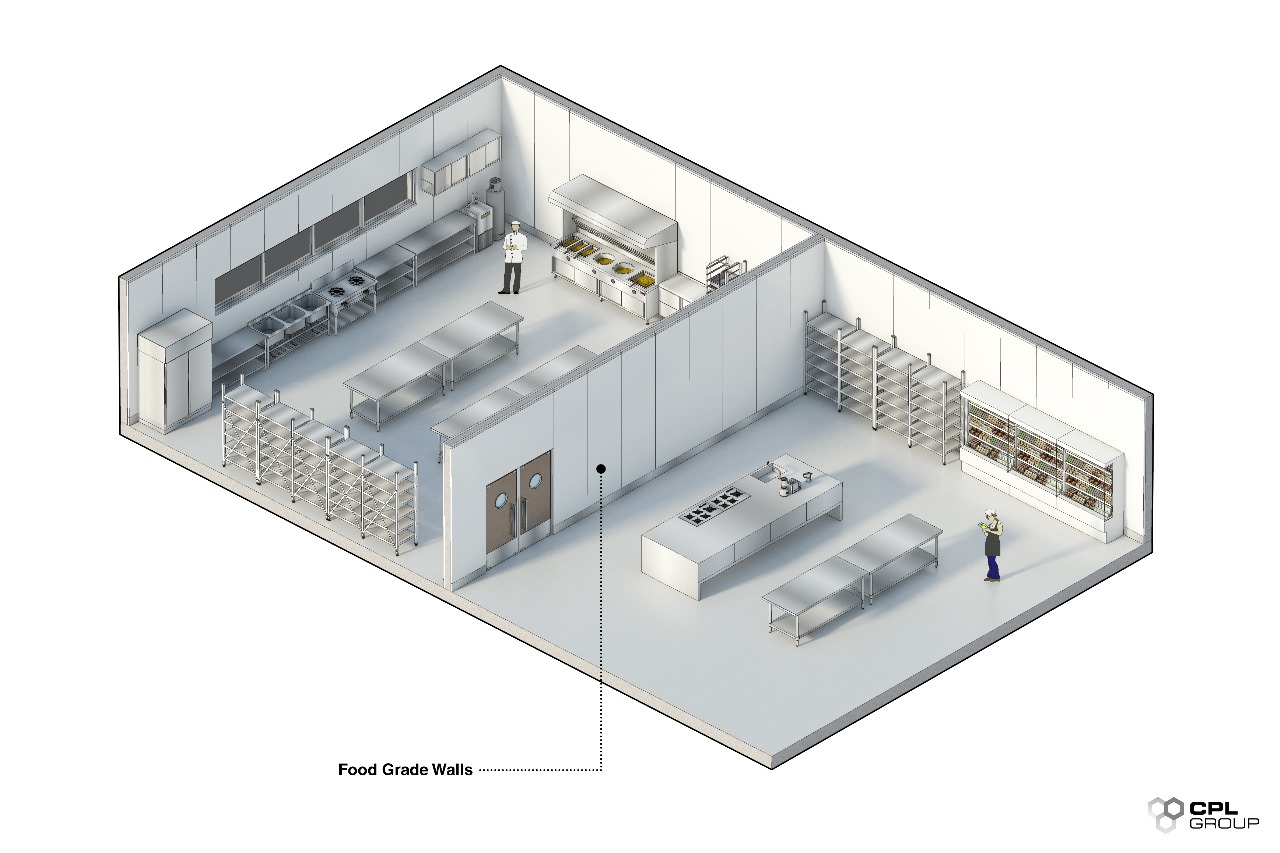

Food Grade Walls: Elevating Hygiene and Safety in the Food & Beverage Industry by CPL Group

Elevate the hygiene and safety standards of your food and beverage facility with CPL Group’s food grade walls. Engineered with premium food-grade materials and smooth, non-porous surfaces, our walls help prevent bacteria and mould growth, ensuring compliance with the highest standards of cleanliness and safety.

Reach out today to learn more.

Food Grade Walls

Food Grade Curtains for your Facility

If you’re seeking a premium-quality solution to ensure hygiene and safety in your food and beverage facility, CPL Group’s food walls offer the perfect answer. CPL Group’s Food Grade Walls are designed to provide a hygienic and compliant environment for food and beverage production facilities.

Why Choose CPL Group's Food Grade Walls?

- CPL Group's food walls provide the perfect combination of functionality, compliance, and aesthetics for the food and beverage industry. With our focus on quality, hygiene, and durability, you can trust that our walls will meet and exceed your expectations.

- Invest in CPL Group's food walls today to elevate the standards of hygiene and safety in your food and beverage facility.

- Contact us to learn more about how our innovative product can benefit your business.

Food-Grade Material: Constructed from food-grade materials, our walls are engineered to meet the stringent requirements of food processing and manufacturing environments

Hygienic Surface: The smooth, non-porous surface prevents the growth of bacteria and mold, ensuring easy cleaning and maintenance of a sanitary environment.

Customizable Options: With a range of colors and finishes available, our food walls can be tailored to match your facility’s aesthetic and branding requirements.

Durable and Long-Lasting: Built to withstand the demands of the food and beverage industry, our walls offer long-term durability, reducing the need for frequent maintenance or replacement.

Compliance: Ensure compliance with food safety standards and regulations, providing peace of mind during inspections and audits.

Enhanced Safety: Install walls resistant to moisture, chemicals, and impact, creating a safer environment for food processing and manufacturing.

Cost-Effective: Reduce long-term maintenance costs with our durable and easy-to-clean walls, offering a cost-effective solution for your facility.

Food Grade Curtains for Your Facility

Food grade curtains are specialised barriers made from high-quality, food-safe materials used to create sanitary divisions within processing and storage areas.

They solve problems such as airborne contaminants, temperature control, and unauthorised access, ultimately enhancing the overall cleanliness and efficiency of the facility.

CPL Group provides customisable curtains to match your facility’s aesthetics while effectively preventing cross-contamination between different zones.

What Happens If Food-Grade Walls Are Not Used

Neglecting to use a food grade wall in food processing facilities can have serious repercussions, impacting both operational efficiency and regulatory compliance. Without these specialised walls, you risk creating an environment susceptible to bacterial growth and mould, which can compromise the safety and quality of your products.

Moreover, non-food grade materials are often porous and difficult to clean thoroughly, leading to persistent contamination issues that can spread throughout the facility. This not only endangers consumer health but also invites frequent and costly inspections, fines, and potential shutdowns due to non-compliance with industry standards.

Furthermore, inadequate wall materials can deteriorate quickly under the harsh temperature conditions typical in food processing environments. Furthermore, exposure to moisture, chemicals, and physical impacts can cause structural damage. This deterioration can further exacerbate contamination risks and decrease the overall lifespan of your facility’s infrastructure.

CPL Group provides food grade rooms and food grade walls to maintain the highest standards of hygiene, safety, and compliance in the food and beverage industry. Our food-grade walls help create optimal conditions for food safety, preventing product spoilage that could lead to significant financial losses and damage to your business reputation.

How To Safely Install Hygienic Wall Panels

Installing a food-grade wall (hygienic wall panels) is a crucial step in maintaining hygiene and safety in your food and beverage facility. Improper installation can lead to gaps, cracks, and uneven surfaces where bacteria and mould can thrive. This can compromise hygiene and increase the risk of foodborne illnesses. Therefore, proper installation is critical to ensure compliance with industry regulations and save your business from consequences like failed inspections, fines, and even facility shutdowns.

- Begin by carefully planning the installation process. Measure the areas to ensure you have the correct dimensions and materials. Clear the workspace of any obstacles and ensure that the environment is clean.

- Adhere strictly to the manufacturer’s guidelines for installation. This includes proper handling of the materials, recommended tools, and any specific preparation required for the walls and surfaces.

- Use appropriate adhesives or mounting systems specified by the manufacturer. Make sure the surfaces are dry, clean, and free from any grease or dust before applying the adhesive.

- Carefully align the panels to ensure a seamless fit. Maintain consistent spacing and use levellers to keep the panels straight and even.

- Once the food-grade panels are in place, seal all joints and edges with a food-grade sealant.

- After installation, inspect the food-grade PVC wall for any gaps. Test the adhesion and sturdiness to ensure the wall panels are securely in place.

If you need any help with the installation, our team is here. We not only provide food & beverage products but also assist with the installation. We will make sure the walls are installed perfectly without any gaps.

Maintaining NZ Standards for Safety and Hygiene in Our Products

In New Zealand, food grade wall in food and beverage facilities must comply with stringent regulations to ensure safety and hygiene. The primary standards come from the Food Standards Australia New Zealand (FSANZ) and the New Zealand Building Code.

- Food Standards Code (Chapter 3): This standard covers food premises and equipment, emphasising the need for surfaces that are smooth, non-porous, and easy to clean to prevent contamination and ensure food safety. Walls must be impervious to moisture and resistant to damage from cleaning chemicals and processes.

- New Zealand Building Code: This code includes various standards that address the construction and materials used in food facilities. It ensures that all building components, including walls, meet performance criteria for durability, moisture resistance, and ease of cleaning.

By adhering to these standards and considerations, CPL Group ensures that our food walls help facilities maintain high hygiene levels , comply with regulations, and operate efficiently.

Would you like to see our products? Visit our warehouse or call us today to discuss your facility’s requirements. We will provide PVC liner or wall panels based on your needs. We guarantee that you’ll find your purchase meets all your expectations.

CLIENTS WE WORK WITH

Copyright © 2026