Fume Control Solutions: CPL Group's for the Automotive Industry

Fumes generated during automotive manufacturing and repair processes can be hazardous to workers’ health. CPL Group’s fume and dust control solutions are designed to contain and extract these fumes to ensure a safe and healthy working environment.

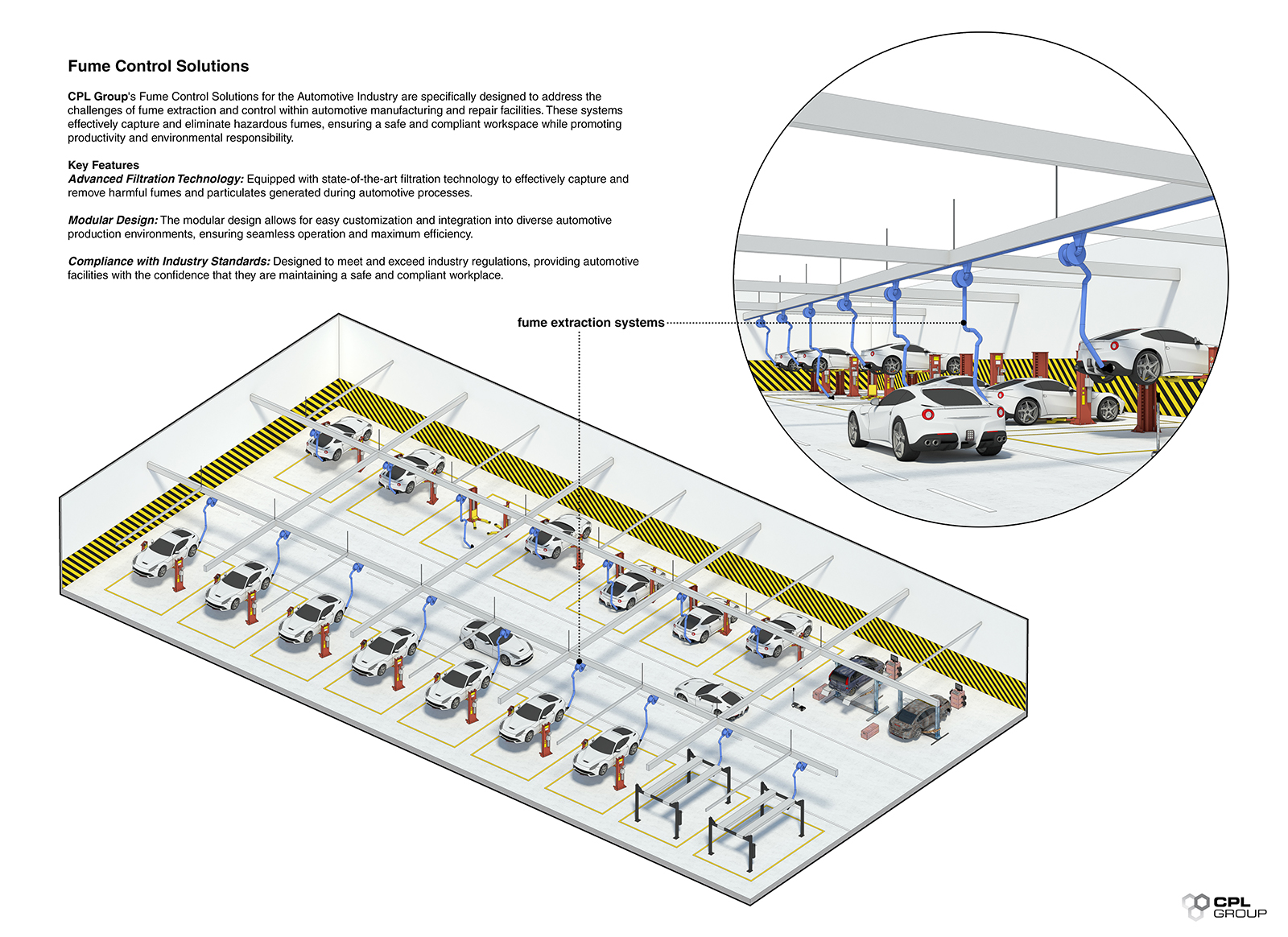

Our fume control systems are strategically positioned above workstations, where vehicles are being serviced or manufactured, ensuring that any fumes produced during these processes are immediately extracted and filtered. This setup not only protects workers from inhaling dangerous fumes but also helps in maintaining the overall air quality within the facility, reducing the risk of long-term health issues and promoting a safer working environment.

Contact us now to find the right fume control solution for your industry.

Fume Control

Fume And Dust Control

In the automotive industry, maintaining a safe and healthy work environment is crucial, and effective fume control plays a significant role. CPL Group’s Fume Control Solutions offer advanced technology to address this essential need, focusing on search engine optimization to attract potential customers.

Purpose and Functions

- CPL Group's Fume Control Solutions for the Automotive Industry are specifically designed to address the challenges of fume extraction and control within automotive manufacturing and repair facilities.

- These systems effectively capture and eliminate hazardous fumes, ensuring a safe and compliant workspace while promoting productivity and environmental responsibility.

- By incorporating relevant keywords throughout the product description, the aim is to enhance the search engine visibility of CPL Group's Fume Control Solutions, making it easier for interested parties in the automotive industry to discover and engage with the innovative products.

Advanced Filtration Technology: Equipped with state-of-the-art filtration technology to effectively capture and remove harmful fumes and particulates generated during automotive processes.

Modular Design: The modular design allows for easy customization and integration into diverse automotive production environments, ensuring seamless operation and maximum efficiency.

Compliance with Industry Standards: Designed to meet and exceed industry regulations, providing automotive facilities with the confidence that they are maintaining a safe and compliant workplace.

Enhanced Workplace Safety: By effectively controlling fumes, the solutions contribute to a safer and healthier work environment for automotive industry professionals, reducing the risk of respiratory issues and other health concerns.

Improved Productivity: Cleaner air and a healthier workforce can lead to improved productivity and employee satisfaction, ultimately resulting in better operational outcomes.

Environmental Responsibility: The solutions align with environmental sustainability efforts by minimizing the release of harmful emissions into the atmosphere, showcasing a commitment to responsible business practices.

Purpose and Function of Fumes and Dust Control System

CPL Group’s Fume Control Solutions for the Automotive Industry are specifically designed to address the challenges of fume extraction and control within automotive manufacturing and repair facilities.

These systems effectively capture and eliminate hazardous fumes, ensuring a safe and compliant workspace while promoting productivity and environmental responsibility.

Key Features of Mounted Fume Extraction Systems

Advanced Filtration Technology: Equipped with state-of-the-art filtration technology to effectively capture and remove harmful fumes and particulates generated during automotive processes.

Modular Design: CPL Group’s fume extraction systems are highly customisable, thanks to their modular design, which allows them to be easily integrated into diverse production environments. Whether the facility requires a linear arrangement or a more complex layout, these systems can be tailored to fit the specific needs of the workspace.

Compliance with Industry Standards: Designed to meet and exceed industry regulations, providing automotive facilities with the confidence that they are maintaining a safe and compliant workplace.

Benefits of Fume Extractor

Enhanced Workplace Safety: By effectively controlling fumes, the solutions contribute to a safer and healthier work environment for automotive industry professionals, reducing the risk of respiratory issues and other health concerns.

Improved Productivity: Cleaner air and a healthier workforce can lead to improved productivity and employee satisfaction, ultimately resulting in better operational outcomes.

Environmental Responsibility: The solutions align with environmental sustainability efforts by minimising the release of harmful emissions into the atmosphere, showcasing a commitment to responsible business practices.

We Provide Installation Service to Ensure Optimal Performance

The installation process for our fume extraction systems is done by our experienced team to ensure optimal performance and seamless integration into your facility. Unprofessional installation can lead to leakage of dust and fumes which could compromise the workers’ health.

- The installation process begins with a thorough site assessment by CPL Group’s technical team. This involves evaluating the layout of the facility, identifying the areas where fume extraction is most needed, and understanding the specific requirements of the workspace.

- Based on this assessment, a customised installation plan is developed, considering factors such as the type of fumes to be extracted, the volume of air to be processed, and the most efficient routing for ductwork and extraction units.

- Next, our experienced technicians start the installation by mounting the extraction units above the designated work areas, installing the ductwork to connect the extraction points to the filtration units, and integrating the system with the facility’s existing infrastructure.

- Safety is a priority during installation; our technicians follow strict protocols to ensure that the system is securely installed and all components are properly connected.

Once the installation is complete, the system undergoes rigorous testing to ensure it operates as designed. This includes checking airflow rates, verifying the effectiveness of the filtration units, and ensuring that all control systems are functioning correctly.

After commissioning, CPL Group provides training for the facility’s staff on how to operate and maintain the fume extraction system. This includes instruction on routine maintenance tasks, troubleshooting common issues, and understanding the system’s control interface.

FAQs

A fume extraction system is a specialised ventilation setup designed to capture and remove harmful fumes, gases, and particulates generated during various automotive processes, such as painting, welding, and engine testing. These systems are crucial for maintaining air quality, protecting worker health, and ensuring compliance with industry safety and environmental regulations.

Our systems are ideal for welding fume control and other harmful substances, including paint fumes, burning fumes, chemical vapours, exhaust gases, and particulates generated during sanding or grinding processes.

Yes, our dust and fume control solutions can be highly customised to meet the specific needs of different automotive operations. This includes tailoring the design to fit the facility layout, selecting the appropriate filtration technology, and configuring the system to handle specific types of fumes or particulates.

Regular maintenance is essential to keep fume extraction systems operating efficiently. The frequency of maintenance can vary depending on the system’s usage and the types of fumes being extracted, but typically includes routine filter changes, inspection of ductwork, and testing of the system’s airflow and performance.

When selecting a fume extraction or exhaust system, consider factors such as the specific types of fumes you need to capture, the size and layout of your facility, the system’s filtration efficiency, ease of maintenance, energy efficiency, and compliance with industry regulations. It’s also important to choose a system that can be customised to fit your unique operational needs.

CLIENTS WE WORK WITH

Copyright © 2026