Silt Curtain: A Must-Have for Water-Based Projects

As a crucial element of environmental protection in the oil and gas industry, CPL Group’s floating silt curtains (also known as turbidity curtain or silt curtain boom) are designed to effectively control and contain sediment and silt during various offshore and nearshore operations.

These innovative curtains serve as a vital solution for minimising the environmental impact of industrial activities, ensuring compliance with environmental regulations, and safeguarding marine ecosystems.

Incorporating these high-quality Silt Curtains from CPL Group into oil and gas operations signifies a proactive approach to environmental conservation, ensuring the protection of marine ecosystems and compliance with regulatory standards.

With their customisable design, robust performance, and significant environmental benefits, these curtains are an indispensable asset for mitigating the ecological impact of industrial activities in marine environments.

Silt Curtain

Floating Silt Curtain Installation

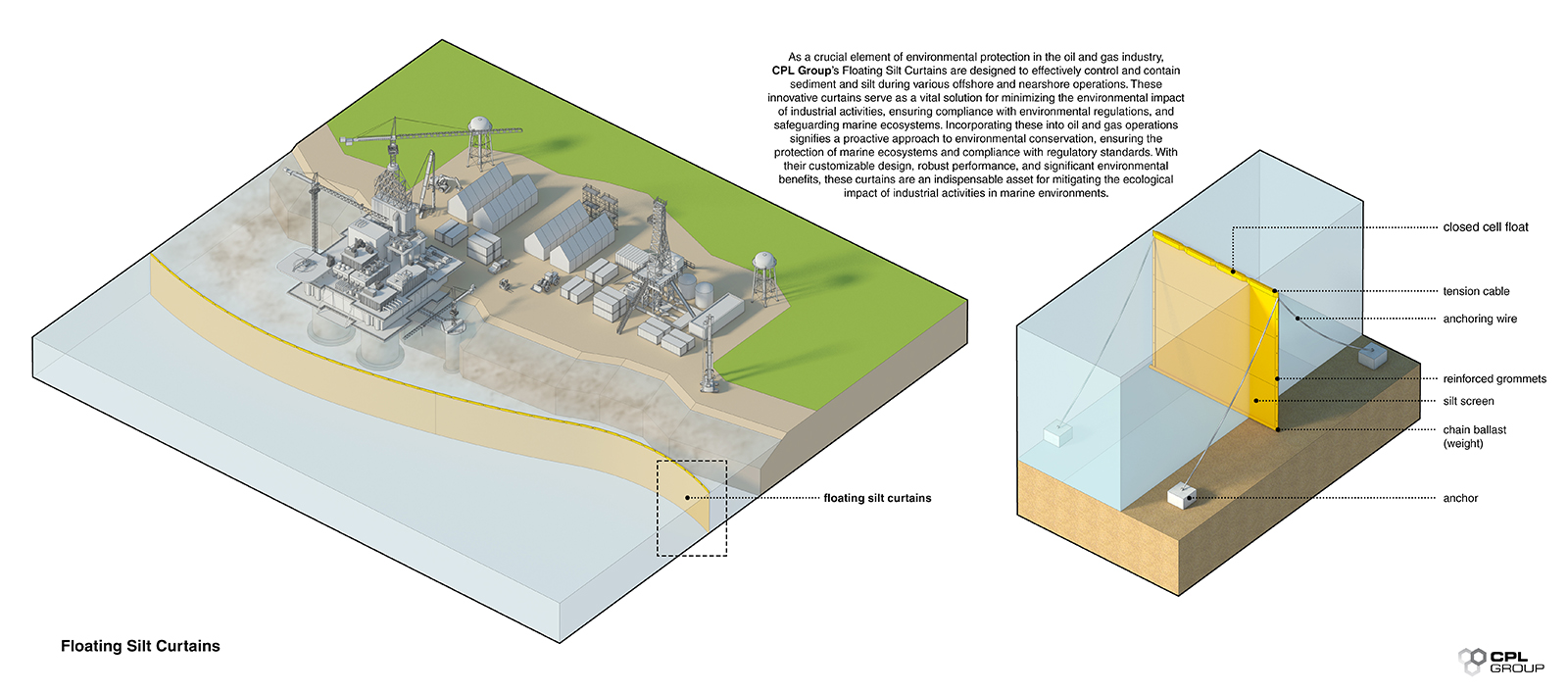

As a crucial element of environmental protection in the oil and gas industry, CPL Group’s Floating Silt Curtains are designed to effectively control and contain sediment and silt during various offshore and nearshore operations.

These innovative curtains serve as a vital solution for minimizing the environmental impact of industrial activities, ensuring compliance with environmental regulations, and safeguarding marine ecosystems.

Incorporating these high-quality Floating Silt Curtains from CPL Group into oil and gas operations signifies a proactive approach to environmental conservation, ensuring the protection of marine ecosystems and compliance with regulatory standards.

With their customizable design, robust performance, and significant environmental benefits, these curtains are an indispensable asset for mitigating the ecological impact of industrial activities in marine environments.

High-Performance Material: Constructed from durable and environmentally friendly materials, CPL Group’s Floating Silt Curtains are engineered to withstand harsh marine conditions and provide long-lasting performance.

Customizable Design: Tailored to meet specific project requirements, these curtains come in a variety of sizes and configurations, allowing for seamless integration into diverse marine environments and operational scenarios.

Efficient Sediment Containment: The innovative design of the curtains effectively traps and contains sediment and silt, preventing their dispersion into surrounding water bodies and minimizing ecological disturbance.

Versatile Deployment: Suitable for a wide range of applications, including dredging, construction, and maintenance projects, the curtains offer versatile deployment options to address varying operational needs.

Environmental Compliance: Designed following industry best practices and environmental guidelines, the Floating Silt Curtains ensure adherence to stringent regulatory standards and promote sustainable operational practices.

Environmental Protection: By minimizing sediment dispersion, the curtains help protect marine ecosystems and maintain water quality, contributing to sustainable environmental stewardship.

Regulatory Compliance: Utilizing CPL Group’s Floating Silt Curtains aids in compliance with environmental regulations and permits, mitigating potential legal and financial liabilities.

Operational Efficiency: The efficient containment of sediment enhances operational efficiency by reducing the need for cleanup and minimizing disruptions to ongoing activities.

Cost Savings: By preventing sediment migration and minimizing environmental impact, the curtains help avoid costly fines, remediation efforts, and project delays.

Enhanced Corporate Responsibility: Incorporating these curtains into oil and gas operations demonstrates a commitment to environmental responsibility and sustainable business practices, enhancing corporate reputation.

Features of Floating Silt Curtains

Premium Quality Material: Manufactured from durable and eco-friendly materials, CPL Group’s floating silt curtains are designed to endure harsh marine environments while delivering lasting performance.

Efficient Sediment Containment: The curtains’ innovative design effectively captures and contains sediment and silt, preventing their spread into nearby water bodies and minimising ecological disruption.

Environmental Compliance: Designed and engineered in accordance with industry best practices and environmental standards, the floating silt curtains guarantee compliance with rigorous regulatory requirements while fostering sustainable operational practices.

Customisable Design: Silt curtains or turbidity barriers [internal link: turbidity barrier page]are designed to meet specific project needs and are available in various sizes and configurations. This flexibility ensures a smooth integration into a wide range of marine environments and operational scenarios.

Versatile Deployment: Suitable for a wide range of applications, including dredging, construction, and maintenance projects, the curtains offer versatile deployment options to address varying operational needs.

Benefits Of Silt Curtain Booms

Environmental Protection: By minimising sediment dispersion, the curtains help protect marine ecosystems and maintain water quality, contributing to sustainable environmental stewardship.

Regulatory Compliance: Utilising CPL Group’s Floating Silt Curtains aids in compliance with environmental regulations and permits, mitigating potential legal and financial liabilities.

Operational Efficiency: The efficient containment of sediment enhances operational efficiency by reducing the need for cleanup and minimising disruptions to ongoing activities.

Cost Savings: By preventing sediment migration and minimising environmental impact, the curtains help avoid costly fines, remediation efforts, and project delays.

Enhanced Corporate Responsibility: Incorporating these curtains into oil and gas operations demonstrates a commitment to environmental responsibility and sustainable business practices, enhancing corporate reputation.

Importance of Silt Curtains for Oil and Gas Industry

Oil and gas factories, particularly those near water bodies, often disturb the seabed by releasing sediments and potentially hazardous materials into the water. This sediment can cloud the water, smother marine life, disrupt aquatic habitats, and transport pollutants far beyond the immediate area. Without proper containment, the environmental consequences can be severe, leading to long-term ecological damage and potential regulatory penalties.

By using silt curtains or oil containment booms, the oil and gas industry can significantly reduce its environmental footprint and contribute to more sustainable and responsible operations.

Why Silt Curtains Are Crucial for Your Construction Projects

Construction activities can often result in sediment and silt entering nearby water bodies, harming marine life and disrupting the ecosystem. Sediment runoff can cloud water, block sunlight, and damage habitats, making it difficult for fish and other wildlife to thrive. A construction silt curtain is an essential solution to prevent these environmental impacts.

It helps contain sediment and reduce turbidity levels in the surrounding water. This not only minimises environmental damage but also ensures compliance with regulations set by the Australian government.

Silt Curtains for Dredging Activities

Dredging is a common activity which involves the removal of sediment, debris, and other materials from the bottom of water bodies to maintain or increase the depth of navigation channels, ports, harbours, and other water-based infrastructures.

Dredging can significantly disturb the seabed and can lead to increased turbidity, which clouds the water and reduces sunlight penetration. Additionally, dredged materials may contain pollutants such as heavy metals and chemicals, which can spread and contaminate larger areas if not properly managed.

Our floating silt curtains are specifically designed for dredging operations to mitigate the environmental impact of dredging activities. They provide an efficient solution for containing and controlling sediment dispersion. With customisable sizes and configurations, you can easily deploy our silt curtains around dredging sites to reduce the spread of suspended particles and pollutants.

Floating Silt Curtain Installation

Installing a floating silt curtain requires careful consideration to prevent sediments from spreading in water bodies and polluting them. Follow these steps.

- Assess the area where the silt curtain will be deployed. Determine the length and depth required to effectively contain sediment.

- Connect the closed cell floats to the top of the silt screen. Ensure they are securely attached to provide buoyancy.

- Run the tension cable through the reinforced grommets at the top of the silt screen. This will help keep the curtain taut and maintain its shape in the water.

- Attach the chain ballast to the bottom of the silt screen to ensure it remains submerged and stable in the water.

- Place anchors at strategic points along the installation area, ensuring they are properly secured on the seabed or riverbed.

- Connect the anchoring wires from the tension cable to the anchors. This will hold the curtain in place and prevent it from drifting.

- Carefully deploy the curtain into the water, ensuring it unfurls smoothly without tangles.

- Position the curtain to form a barrier around the designated area, effectively containing sediment and silt.

- Check the curtain for any slack or gaps. Adjust the tension cable and anchoring wires as necessary to ensure a tight and effective seal.

Interested in buying our silt curtains for water based projects? Request a quote today. Our team can also assist with the deployment of silt curtains in Australia. Just let us know if you’d like us to handle the installation, and our team will arrive on-site equipped with all the necessary tools.

CLIENTS WE WORK WITH

Copyright © 2024