Hangar Paint Curtains

Looking to streamline your aircraft painting process? Discover CPL Group’s Hangar Paint Curtains, designed to meet the unique demands of the aviation industry. Our hangar paint curtains are designed to create a temporary barrier between the painting area and other areas of the hangar. This helps prevent overspray, debris, and fumes from spreading to other aircrafts.

Request a quote today.

Durable Construction: Crafted from high-quality materials, these curtains are built to withstand the rigorous demands of aircraft painting, providing long-lasting performance.

Customizable Sizing: Available in various dimensions to suit different hangar configurations, ensuring a perfect fit for your specific operational needs.

Enhanced Safety: Designed to contain paint overspray and prevent cross-contamination, promoting a safer and more controlled painting environment.

Easy Installation: Featuring a user-friendly design for hassle-free setup, saving valuable time and resources during installation.

Optimized Workflow: By effectively containing paint overspray, these curtains help maintain a clean and organized workspace, enhancing overall operational efficiency.

Cost-Effective Solution: Minimize the need for extensive cleaning and maintenance while reducing the risk of rework, ultimately leading to cost savings for your business.

Compliance Assurance: With a focus on safety and containment, these curtains aid in meeting industry regulations and standards, ensuring regulatory compliance.

The cost implications of implementing hangar paint curtains in the aviation industry are significant and multifaceted, affecting both initial investment and ongoing operational expenses.

Initial Investment:Affordable Installation: Hangar paint curtains are easy to install and are available at a fraction of the cost of operable fixed doors, making them a cost-effective solution for dividing space within aircraft hangars. The installation cost is also substantially lower compared to comparable roll-up and sliding doors, resulting in immediate cost savings.

Customizable Sizing: Being custom-made to fit any size and shape, these curtains offer businesses the flexibility to tailor the solution to their specific requirements, further optimizing the initial investment.

Operational Cost Savings:Maintenance and Reusability: The curtains are designed for high reusability, offering cheaper maintenance compared to solid doors and partitions. Their durable nature allows for removal in case of operational changes or the need for more space due to fleet acquisition, minimizing long-term operational costs.

Utility Bills and Efficiency: Efficient temperature control provided by the curtains leads to savings on utility bills, contributing to long-term cost-effectiveness. Additionally, the curtains aid in controlling smoke and humidity levels, further enhancing operational efficiency and cost savings.

Long-Term Value:Adaptability: The adaptability of the curtains to changing business requirements ensures long-term value, as they can be easily reconfigured or removed, providing a sustainable and cost-efficient solution for evolving operational needs.

Overall, the implementation of hangar paint curtains presents a compelling cost-saving opportunity for businesses in the aviation industry. From affordable installation to long-term operational cost savings and adaptability, these curtains offer a cost-effective and sustainable solution for enhancing operational efficiency within aircraft hangars.

Partition Walls for Paint Booths

CPL Group offers paint booth walls that allow you to manage wash bay space easily. These partition walls not only help in maintaining a clean and controlled environment for painting aircraft but also ensure safety by containing overspray and reducing contamination.

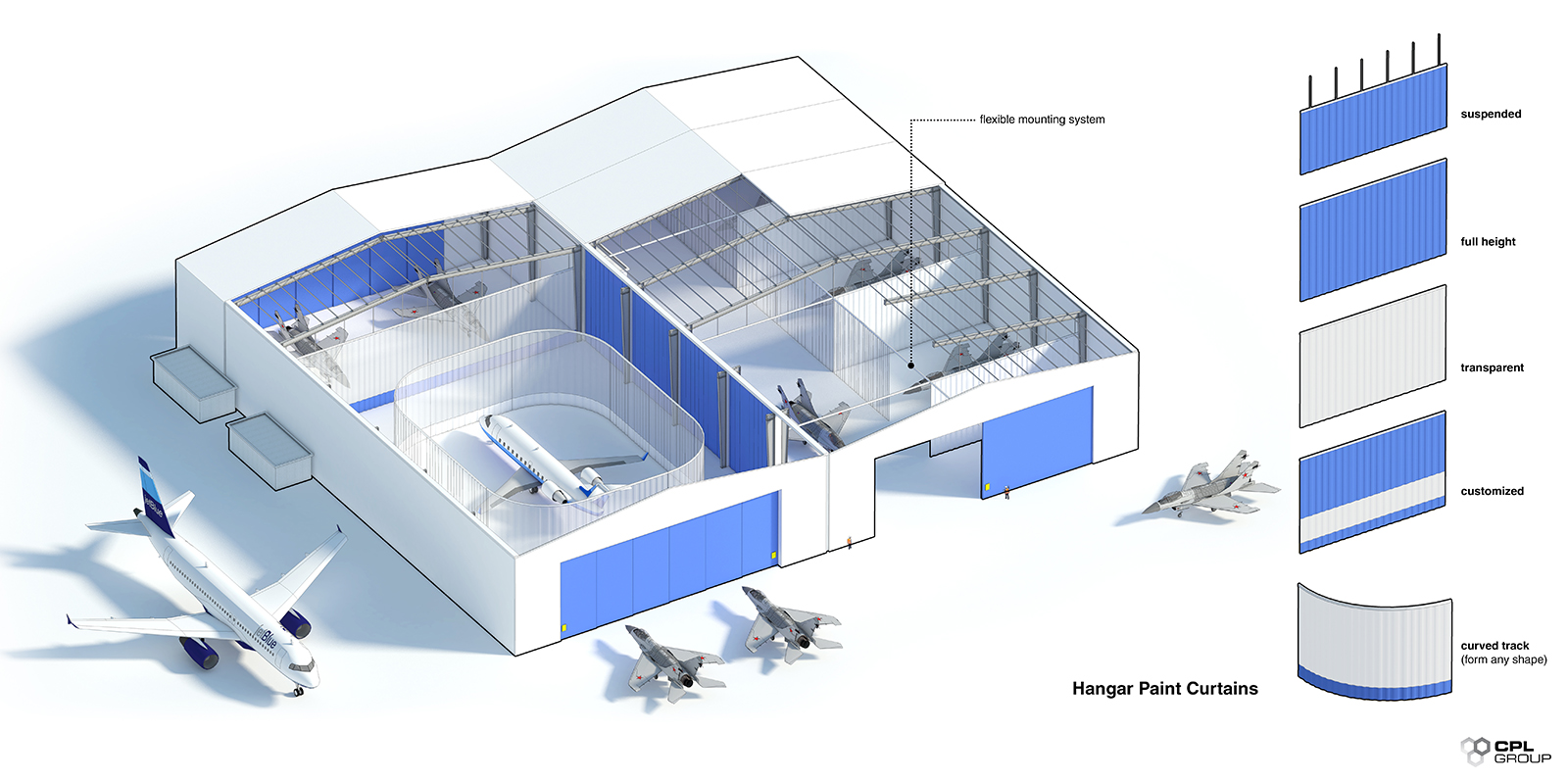

The special materials in these partition walls are suitable for preventing metal smut and dust, weld sparks, and other hazards from spreading to other areas of the aviation facility. The CPL Group offers a variety of partition walls designed to meet the specific needs of aviation facilities. We have suspended partition walls, which are ideal for spaces where floor space is limited, and full-height walls that provide robust separation between work areas.

Our transparent partition walls allow for visibility while maintaining separation, making them perfect for overseeing multiple tasks simultaneously. For unique space requirements, we offer customised solutions, including curved tracks that can be shaped to fit any layout, ensuring that even the most challenging spaces can be effectively utilised.

Key Features

Durable Construction: Crafted from high-quality materials, our hangar paint curtains and hangar curtain doors are built to withstand the rigorous demands of aircraft painting.

Customisable Sizing: Available in various dimensions to suit different hangar configurations, ensuring a perfect fit for your specific operational needs.

Enhanced Safety: Designed to contain paint overspray and prevent cross-contamination, promoting a safer and more controlled painting environment.

Easy Installation: Featuring a user-friendly design and flexible mounting system for hassle-free setup, saving valuable time and resources during installation.

Benefits

Optimised Workflow: By effectively containing paint overspray, these curtains help maintain a clean and organised workspace, enhancing overall operational efficiency.

Cost-Effective Solution: Minimise the need for extensive cleaning and maintenance while reducing the risk of rework, ultimately leading to cost savings for your business.

Compliance Assurance: With a focus on safety and containment, these curtains aid in meeting industry regulations and standards, ensuring regulatory compliance.

Weighing the Costs: How Hangar Paint Curtains Impact Aviation Budgets

The cost implications of implementing hangar paint curtains in the aviation industry are significant and multifaceted, affecting both initial investment and ongoing operational expenses.

Initial Investment

Hangar paint curtains are easy to install and are available at a fraction of the cost of operable fixed doors, making them a cost-effective solution for dividing space within aircraft hangars. The installation cost is also substantially lower compared to comparable roll-up and sliding doors, resulting in immediate cost savings.

Moreover, they are custom-made to fit any size and shape, and offer businesses the flexibility to tailor the solution to their specific requirements, further optimising the initial investment.

Operational Cost Savings

The curtains are designed for high reusability in the aviation industry, offering cheaper maintenance compared to solid doors and partitions. Their durable nature allows for removal in case of operational changes or the need for more space due to fleet acquisition, minimising long-term operational costs.

Plus, efficient temperature control provided by the curtains leads to savings on utility bills, contributing to long-term cost-effectiveness. Additionally, the curtains aid in controlling smoke and humidity levels, further enhancing operational efficiency and cost savings.

Long-Term Value

The adaptability of the curtains to changing business requirements ensures long-term value, as they can be easily reconfigured or removed, providing a sustainable and cost-efficient solution for evolving operational needs.

Overall, the implementation of hangar paint curtains presents a compelling cost-saving opportunity for businesses in the aviation industry. From affordable installation to long-term operational cost savings and adaptability, these curtains offer a cost-effective and sustainable solution for enhancing operational efficiency within aircraft hangars.

How can partition walls improve safety in an aviation hangar?

Partition walls play a crucial role in enhancing safety within aviation hangars by addressing several key challenges associated with large, open workspaces. One of the primary safety concerns in hangars is the risk of contamination from paint overspray, dust, and other airborne particles that can spread across the workspace.

It potentially affects sensitive equipment and compromises the quality of aircraft maintenance or painting processes. Partition walls provide an effective solution by creating designated work zones that confine hazardous activities to specific areas, preventing the spread of harmful substances and ensuring a cleaner, safer environment for both workers and equipment.

Additionally, the lack of clear separation between activities can result in chaotic workflows, where workers and equipment frequently cross paths, heightening the chances of mishaps. Partition walls help mitigate these risks by clearly delineating work areas, and reducing unnecessary hazards in the hangar .

This separation allows for more efficient coordination among teams, ultimately contributing to a safer and more productive work environment.

Can partition walls be moved or reconfigured as needed?

Yes, CPL Group’s partition walls are designed to be flexible and movable. This allows for quick reconfiguration of workspaces to accommodate different aircraft or tasks, providing greater operational flexibility.

CLIENTS WE WORK WITH

Copyright © 2024