Australian Cold Storage Solutions: Enhancing Warehouse and Logistics Efficiency

In the ever-evolving landscape of warehouse and logistics management, one critical aspect often overlooked is cold storage solutions. In a country like Australia, where temperature-sensitive goods are abundant, the demand for efficient and compliant cold storage facilities is on the rise. From pharmaceuticals to perishable foods, maintaining precise temperature control is not just a preference but a necessity. Our recent blog highlighted how tailored logistics and warehousing solutions help. Let’s explore the growing demand, compliance requirements, and industry standards for cold storage solutions in Australian warehouses and logistics facilities.

The Demand for Cold Storage Solutions

Australia’s diverse economy relies heavily on the import and export of perishable goods, pharmaceuticals, and other temperature-sensitive products. With the increasing demand for fresh produce, meat, dairy, and pharmaceuticals, the need for reliable cold storage solutions has never been higher. Warehouses and logistics facilities play a crucial role in maintaining the integrity of these products throughout the supply chain. Whether it’s preserving freshness, extending shelf life, or complying with regulatory standards, cold storage is indispensable.

Compliance and Regulatory Standards

When it comes to cold storage, compliance is non-negotiable. Australian warehouses and logistics facilities must adhere to stringent regulatory standards to ensure the safety and quality of stored goods. The Australian Refrigeration Council (ARC) sets guidelines for the installation, maintenance, and servicing of refrigeration and air conditioning systems. Additionally, facilities must comply with the Food Standards Australia New Zealand (FSANZ) regulations, particularly for storing perishable food items. Meeting these standards not only ensures product quality but also minimizes the risk of spoilage and contamination.

Industry Standards and Best Practices for Logistics and Warehousing Facilities

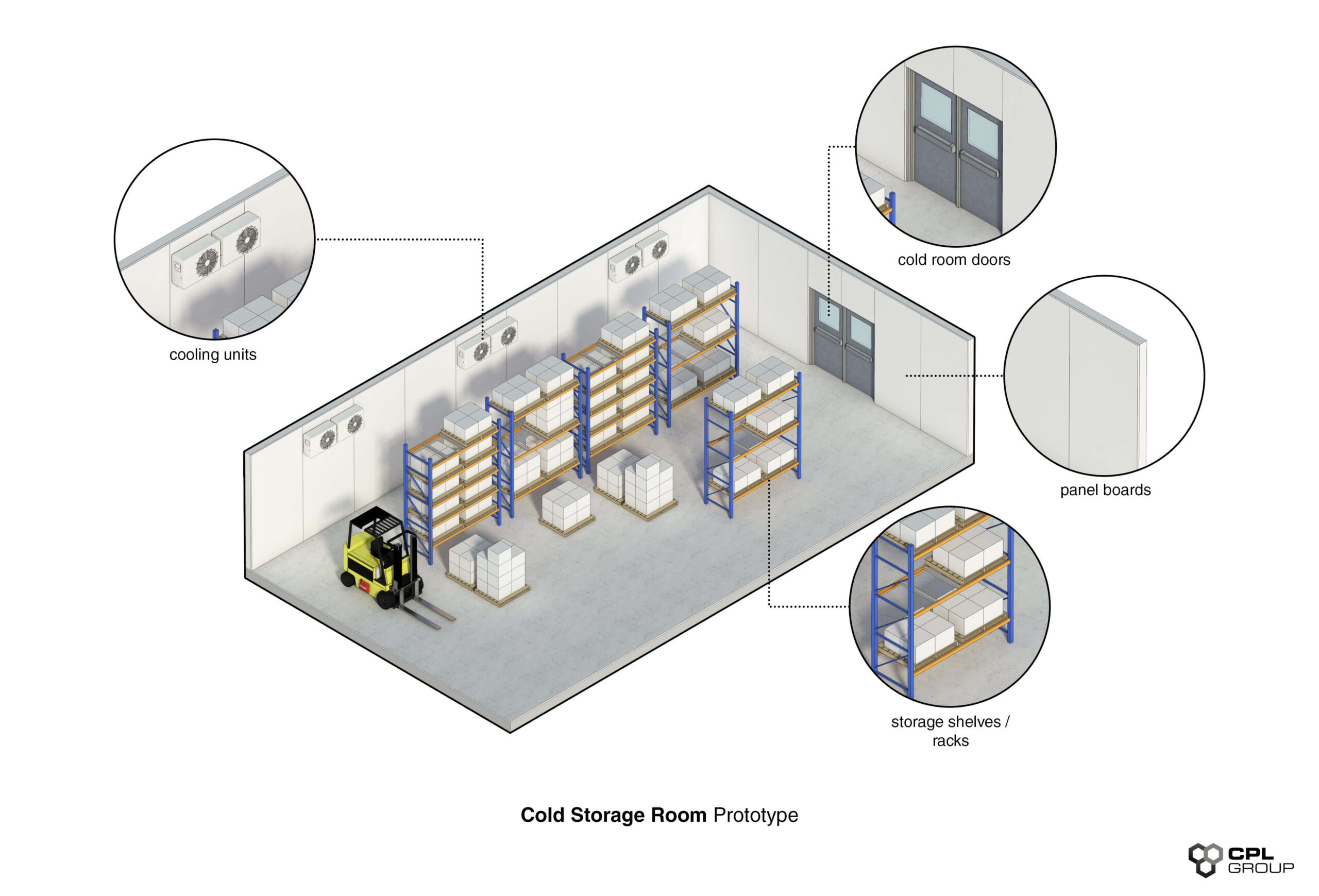

When we talk about cold storage, adhering to industry standards and best practices is non-negotiable. Australian warehouses and logistics facilities must invest in state-of-the-art refrigeration systems capable of maintaining precise temperature and humidity levels. This includes the use of advanced insulation materials, energy-efficient refrigerants, and temperature monitoring technologies. Implementing proper ventilation and airflow management systems is also essential to prevent temperature fluctuations and ensure uniform cooling throughout the storage facility.

Moreover, automated inventory management systems can streamline operations and minimize human error. These systems not only track product movement but also monitor temperature variations in real time, allowing for prompt corrective action when deviations occur. Additionally, regular maintenance and servicing of refrigeration equipment are crucial to prevent breakdowns and ensure optimal performance.

Innovative Solutions for Cold Storage

As the demand for cold storage solutions continues to grow, the industry is witnessing a surge in innovative technologies aimed at enhancing efficiency and reliability. One such solution is Thermal Dividing Walls, which offer flexibility and scalability to meet changing storage requirements. These prefabricated units can be quickly installed and customised to suit specific temperature and spatial needs, making them ideal for warehouses and logistics facilities with limited space or seasonal fluctuations in demand.

Furthermore, the integration of IoT (Internet of Things) technology is revolutionising cold storage management. IoT-enabled sensors and devices allow for remote monitoring of temperature, humidity, and other environmental variables, providing real-time insights into storage conditions. This not only improves efficiency but also enables proactive maintenance and compliance with regulatory standards.

Key Takeaways

- Cold storage solutions are indispensable for Australian warehouses and logistics facilities dealing with temperature-sensitive goods.

- The growing demand for fresh produce, pharmaceuticals, and perishable foods underscores the need for efficient and compliant cold storage infrastructure.

- By adhering to regulatory standards, implementing industry best practices, and embracing innovative technologies, warehouses and logistics facilities can ensure the integrity and safety of stored goods throughout the supply chain.

In a constantly evolving market, staying ahead of the curve in cold storage management is essential for maintaining competitiveness and meeting consumer demands.