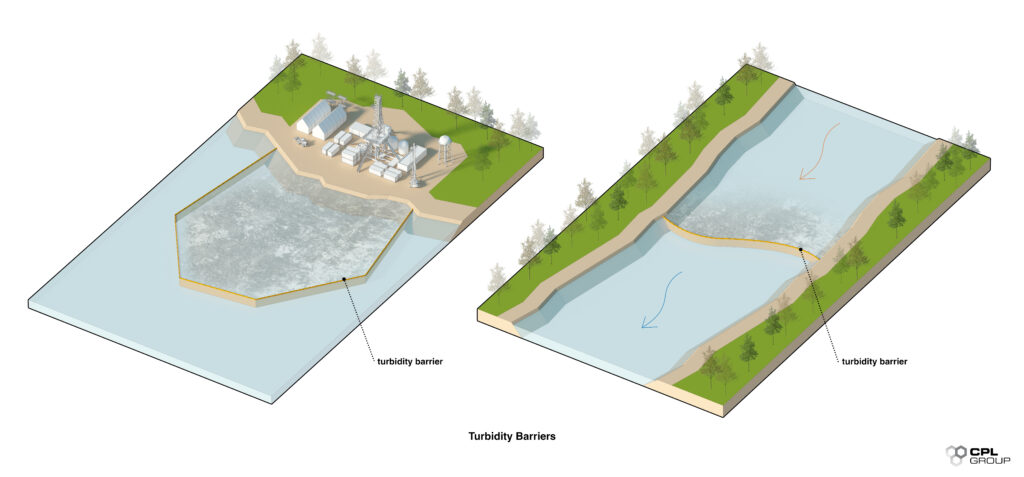

Turbidity Barriers: Protecting Aquatic Ecosystems During Construction and Dredging

Turbidity barriers are crucial in minimising the environmental impact of construction and dredging activities in aquatic environments. These specialised solutions from CPL Group offer superior protection for marine ecosystems while ensuring project efficiency. Let’s explore the key aspects of these essential environmental safeguards.

Understanding Turbidity Barriers

Turbidity barriers are primarily designed for dynamic water conditions. They’re engineered to withstand stronger currents and waves, making them ideal for coastal or river projects. While similar to silt curtains, which are generally used in calmer waters like lakes and ponds, turbidity barriers are more robust and versatile.

Key Features and Benefits of Turbidity Barriers

- High-Strength Fabrics: CPL Group’s turbidity barriers are made from durable materials resistant to UV degradation and tearing, ensuring longevity in harsh aquatic environments.

- Effective Flotation: The barriers maintain their position in various water conditions, providing consistent protection.

- Customisation Options:

- Length and Depth: Tailored to specific project site dimensions.

- Material Selection: Various fabric options based on water conditions and project duration.

- Anchoring Systems: Custom solutions for different bottom conditions and current strengths.

- Environmental Compliance: Meet regulatory requirements for sediment control in aquatic projects, avoiding potential fines and delays.

- Improved Water Clarity: By effectively trapping sediment, these barriers maintain water quality and protect aquatic life.

- Project Efficiency: Minimise the spread of suspended sediments, allowing smoother operations and reducing cleanup efforts.

Tips on Use and Application

- Site Assessment: Conduct a thorough evaluation of water conditions, currents, and project requirements before installation.

- Proper Deployment:

- Install parallel to water flow to minimise strain, especially in moving water.

- Add up to 20% extra length to account for water level fluctuations in rivers or tidal areas.

- Ensure correct positioning and anchoring to maximise effectiveness.

- Monitoring: Regularly check the barrier’s position and integrity throughout the project duration.

Maintenance Guidelines

- Regular Cleaning: Remove accumulated sediment to maintain barrier effectiveness.

- Inspection for Damage: Check for tears, worn areas, or compromised seals and repair promptly.

- Proper Storage: Clean and dry barriers before storage to prevent mold and degradation.

Environmental and Business Benefits of Turbidity Barriers

- Ecosystem Protection: Safeguard marine life and preserve the natural beauty of waterways by containing harmful sediment particles.

- Cost Savings: Avoid potential fines and project delays related to environmental violations.

- Reputation Enhancement: Demonstrate commitment to environmental stewardship, boosting corporate image.

- Versatile Applications: Suitable for various sectors, including construction, dredging, and environmental protection projects.

By choosing CPL Group’s turbidity barriers, you’re not just controlling sediment – you’re actively contributing to the health of aquatic ecosystems while ensuring the success of your water-based projects. Our collaborative approach means we work closely with you to understand your project’s unique challenges and provide tailored solutions that exceed expectations.

Remember, the key to maximizing the effectiveness of these barriers lies in proper selection, installation, and maintenance. Partner with CPL Group to make a positive difference for our water bodies and the planet.